Free Fatty Acids analysis in Oils and Fats - CDR FOODLAB

- Type: peanut oil machine

- Usage/Application: peanut, groundnut

- Power (W): 39kw

- Weight: 200 kg

- Warranty: 1 Year

- Certification: CE ISO

- Dimension (L*W*H): 1500*900*1900 mm

- Country: lusaka

The calibration curve of the analytical CDR FoodLab® method, carried out with respect to the reference method AOCS Official Method Ca 5a-40.Furthermore Free Fatty Acids content was determined using the CDR FoodLab® instrument and the titration method used by Campden BRI (Campden BRI Method TES-AC-211): the data for Free Fatty Acids using the CDR FoodLab® was found to be very consistent with

Free fatty acid testing - MP Bio

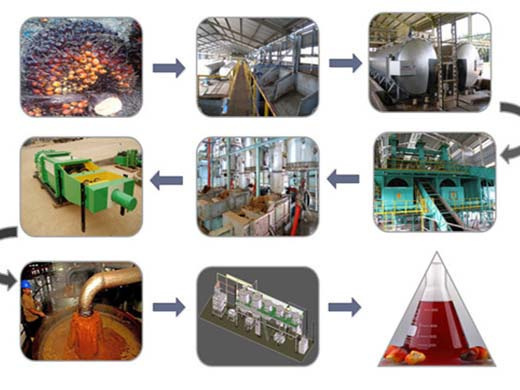

- Type: peanut oil processing machine

- Voltage: Design according to customer demand

- Power (W): 11 KW

- Certification: ISO9001, BV, CE

- Weight: Standard

- Dimension (L*W*H): 4935*1523*2664

Learn how free fatty acids (FFA) are key indicators rancidity in food and how FFA testing methods can be used to evaluate the freshness of food samples.

Free fatty acids (FFA, expressed in %) are not bound to glycerol in the oil and are formed by hydrolysis of triglycerides during oil extraction, refining, or storage steps. Figure 5. Correlation diagram for the calculation of free fatty acids in edible oil samples using an OMNIS NIR Analyzer Liquid.

Edible Oils and Fats Analysis: All You Need to know

- Usage: peanut oil

- Production capacity: 100% raw cooking oil price

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W) *H): Depends on its capacity

- Power (W): Depends on its capacity

Density and refractive index are often used for first-pass quality control in oil refineries. Generally, refineries receive oils and fats from different origins, and before unrefined products are transferred to storage facilities, parameters such as refractive index, density, free fatty acids (FFA), peroxide number and color are assessed.

Fatty Acids (FFA) in Fats and Oils FOOD & BEVERAGE SERIES The method is suitable for edible fats and oils such as butter, olive, palm or sunflower oil. The acid number is the quantity of base, expressed in milligrams of potassium hydroxide, which is required to neutralize all acidic constituents present in 1 g of sample.

How to Test for Free Fatty Acid in Cooking Oil | DALSORB®

- Type: cooking oil extraction machine

- Production capacity: More than 95%

- Voltage: 220 V/110 V

- Main components: motor, PLC, gearbox

- Weight: 100 kg

- Dimension (L*W*H): 46*22.5* 26 cm

Put the 5mL oil sample into the plastic beaker and leave the measuring spoon in the beaker for stirring purposes. Stir the oil, FFA indicator, and alcohol for 5 seconds. Count each drop of FFA indicator as this will correlate to the final FFA reading. Put one drop of the FFA indicator in the solution at a time, counting each drop.

FFA and PV are valuable parameters for evaluation of the quality of protein meals and fats/oils. The classic methods are often time-consuming, expensive and require trained lab personnel. The CDR Foodlab analyzer offers a faster and cheaper solution to analyze these parameters on-site upon reception of the raw materials.

SafTest System - MP Bio

- Raw Material: peanut

- Press Materials: Grains and Oilseeds

- Custom : Customized

- Press Series: Second

- Application area: Oilseeds etc

- Payment term: T/T 40% in advance, balance paid

Peanut Butter Peroxide Value Free Fatty Acids Malonaldehyde Alkenals Peroxide Value: 0.01 – 50 meq/kg FFA: 0.02 – 20% Oleic acid Malonaldehydes: 0 – 60 mg/kg or 0 – 1,200 μmol/kg Alkenals: 0 – 1,200 μmol/kg >1mL or 4g Feedstock Free Fatty Acids FFA: 0.02 – 20% Oleic acid >1mL or 4g Biodiesel Total Glycerin Bound Glycerin

The aging of cooking oil due to usage, heat, hydrolysis, and contaminants requires frequent testing to determine when to change or meld the cooking oil as FFA increases in the oil. High levels of FFA result in poor quality product, taste, texture, and appearance. Chemical, capacitance, and other lab methods offer low-cost investment, but