Artisanal Milling of Palm Oil in Cameroon

- Type: cottonseed oil mill

- Usage/Application: cottonseed

- Production capacity: 600 kg/h

- Voltage: 220

- Main components: gearbox, pressure vessel, Pump, Gear, Bearing, Motor, Motor, PLC, Others

- Weight: 11 kg

- Dimension (length x width x height): 460 mm x 180 mm x 310 mm

- Country: cameroon

2.1 Small-scale artisanal milling 3 2.2 Processing of fresh fruit bunches (FFBs) into red oil 3 2.3 The production of kernel oil and soap 16 2.4 Commercialization of CPO 17 2.5 Contribution of income to household livelihood 19 2.6 The role of women 19 2.7 Constraints in small scale/artisanal milling of red palm oil 19 2.8 Oil storage 20 3.

The non-industrial palm oil sector in Cameroon

- Type: cottonseed oil processing machine

- Production capacity: Virgin oil centrifugal machine

- Voltage: local voltage 220V/380V

- Weight: depends on capacity

- Dimension (L *W*H): depends on capacity

- Power (W): depends on capacity

Cameroon, since it is indigenous to the countries bordering the Gulf of ethiopia. People in the rainforest region of Cameroon used to harvest fresh fruit bunches (FFB) from the wild dura variety to produce palm oil and kernel oil, and fell and tap old stands of both dura and pisifera varieties to produce palm wine, which is a much cherished liquor.

This case study was focused on Oil Mill A that is located in Lepar, Pahang. Data collection The data include the oil extraction rate (OER) percentages from 2007 to 2009, fruits received by the mill and the data of oil loss from the milling process. The data collected are: Monthly FFB Grading Analyze, OER percentage, monthly FFB processed, and

Artisanal Milling of Palm Oil in Cameroon - ResearchGate

- Usage: cottonseed oil

- Production capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Dimension (L *W*H): 48m*12M*15M(30TPD)

- Power (W): 18.5 KW/T

Artisanal Milling of Palm Oil in Cameroon. Working Paper 128. Bogor, Indonesia: CIFOR. FFB Fresh fruit bunch. HP Hydraulic press . the milling process. ey are in charge of selling the .

The initials stand for fresh fruit bunch, and refer to the bunch harvested from the oil palm tree. Each bunch weighs from 5kg to 50kg and can contain up to 1500 or more individual fruits. Calculations of oil yield and losses in the oil mill is often referred to the fresh fruit bunch, as this is the material taken in for processing. (extracted

World Bank Document

- Type: cooking oil extraction machine

- Voltage: 380v, 380V

- Weight: 1700kg, 1700kg

- Power (W): 7.8kw

- Dimension (L*W*H): 7500* 2100*2430 mm

- Power: 7.8kw

The object of milling is to extract palm oil and palm kernels from the fresh fruit bunches. Milling Systems The oil produced by the traditional methods still common in West Africa is of poor quality, high in free fatty acids, and is classified as 'hard' or 'soft'. In both cases, shells are cracked and the kernels separated from the shells by hand.

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB. The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted.

General Description of The Palm Oil Milling Process

- Raw Material: cottonseed oil

- Power (W): 15kw

- Temperature control power:3kw

- Oil content of dry cake: <7.6%

- Oil filtration power: 1.5 Kw

- Transportation package: We use high standard fumigated wooden box packaging.

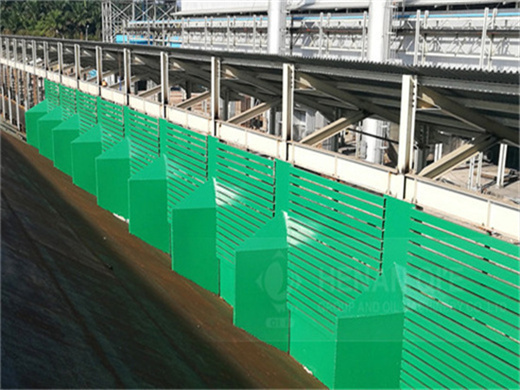

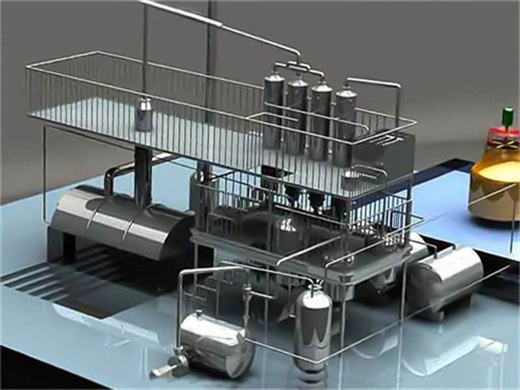

A palm oil mill produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 45 - 100 tons FFB/hour. A typical mill has many operation units as shown in picture. This comprises of sterilization, stripping, digestion and pressing, clarification, purification, drying and storage.

The document outlines the key processing stations in a traditional crude palm oil mill, including: 1. Reception/grading of fresh fruit bunches (FFB), sterilization to release the nut, threshing to separate the fruit from the bunch. 2. Digestion/pressing to extract the oil, clarification through settling and centrifugation to separate the oil. 3. Purification and drying of the crude palm oil