What are the machines used for palm oil processing?

- Type: palm oil refinery machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100kg/h

- Voltage: 380V/50HZ

- Warranty: 1 year, 12 months

- Weight: 100 tons

- Dimension (L*W*H): 60*10*7m

- Country: tanzania

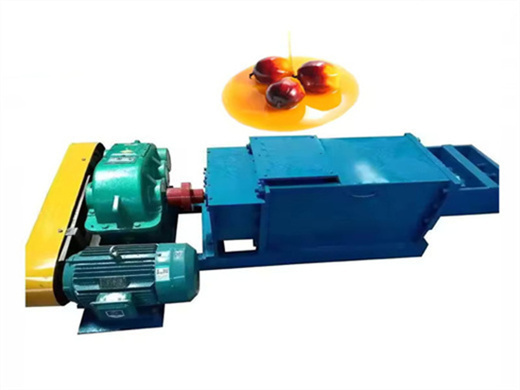

5. Presser: the major function of screw palm oil press machine is to extract palm oil from palm fruit. As for different palm oil processing capacity, there two kinds of screw palm oil press machine for people to choose, one is screw palm oil press machine, the other is double screw palm oil press machine. Screw palm oil press machine. 6.

Small Scale Palm Oil Refinery Machine Selection and Process

- Type: palm oil refinery machine

- Production capacity: 150-250 kg/h

- Voltage: Local voltage

- Weight: 1200kg

- Dimension (L*W*H): 1950x1300x1900

- Power ( W): 3KW

Palm Oil Refining Process. Processing Flow of Small Scale Palm Oil Refinery: Crude palm oil → degumming (washing) → deacidification (alkali refining) → decolorization (clay adsorption) → dehydration (heating and drying) → deodorization (vacuum distillation) → refined oil. Palm Oil Extraction, Refining and Fractionation Process

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining. Palm oil machinery cover different scales of processing from 10 to 1,000 tons per day(TPD

Palm oil processing and production process | Alfa Laval

- Usage: palm oil

- Production capacity: 7-8 TPD

- Voltage: 30 HP

- Main components: Motor, Bearing, Gearbox

- Weight: 4000 KG

- Dimension (length x width x height): 2175MM*1200MM*2200MM

A full range of palm oil milling equipment, with everything you need for your oil room and (crude palm oil) CPO washing; Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing; Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield

The refining process removes water, odouriferous matter, phosphatides, free fatty acids and other impurities including dirt and traces of metals from palm oil mill. After processed in palm oil refinery plant, the final oil product is a kind of premium edible oil of consistent quality which not only satisfies customer requirements and industry

Palm Oil Refining Machine

- Type: cooking oil refining machine

- Production capacity: 100TPD

- Dimension (length x width x height): 1128*820*1600mm

- Voltage: 220V/380V, 380V

- Weight: 1700 KG

- Main components: Motor, Pressure vessel, pump, PLC, others, gears, motors, gearboxes, olive oil processing machine

Palm Oil Refining Machine. Palm Oil Refinery is the main oil machinery and equipment to ensure the quality, grade and edible safety of oil in the palm oil processing process. The palm oil refining machine produced by Henan Hongde Cereals and Oils Machinery Co., Ltd. can flexibly adapt to different production needs with advanced technology

The palm oil degumming and deacidification process uses a washing method to separate soap residual from mixing oil, providing preparation for the next step palm oil refinery machine. Bleaching Process. The palm oil bleaching process is mainly used to remove oil pigment, residual soap, and metal ions during palm oil refining machine

Palm Oil Refinery - Palm Oil Mill Machine Leading

- Raw Material: palm

- Production capacity: 150-2500 KG/h

- Power (W ): 290000

- Voltage:380V

- Dimension (L*W*H):20m*10m*6

- Weight:150T

Depending on the size of the industry, all or a few steps of the palm oil processing in africa is done using machinery. Local man power is used in other manual processes. The oil dispensation establishment containssterilization station, digestion station and clarification station equipped with machinery for efficientprocessing. The palm oil press is used to extract oil from the fruits. The palm oil refinery is used to refine the oil to its pure form.

The main steps of crude palm oil refining. CPO(crude palm oil)→ refining → bleaching → deodorizing →RBD palm oil → crystallization → fractionation → RBD olein & RBD stearin. Palm Oil Refinery equipment is the important palm oil machinery and equipment to ensure the quality, grade and safety of palm oil in the processing