Coconut Plantation | Wholesale & Export - WR Carpenter Estates

- Type: coconut oil processing plant

- Usage/Application: coconut, copra

- Production capacity: 30T-300T/D

- Voltage: 380v or according to voltage local

- Weight: 1050KG cooking oil solvent extraction plant

- Dimension (L*W*H): 430*230*350 cooking oil solvent extraction plant

- Power (W): According to the capacity of the cooking oil solvent extraction plant

- Country: ethiopia

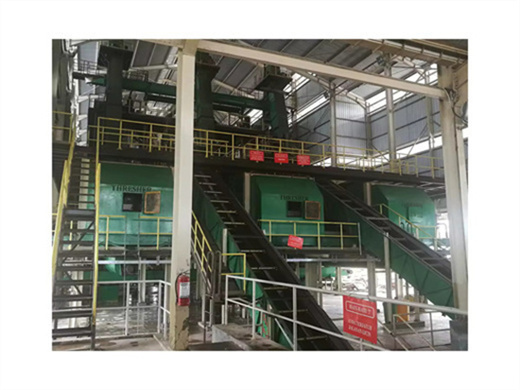

Our CCNO (Crude Coconut Oil) processing facility is the largest plant in Papua New ethiopia, based in Madang Province.The facility produces coconut oil and copra meal, mainly for export, and also houses bulk storage tanks for Crude Coconut Oil a capability to produce over 30,000 metric tons of crude coconut oil annually.

Breaking Down the Investment: Virgin Coconut Oil

- Type: coconut oil processing machine

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): 10-50kw

For example, your virgin coconut oil manufacturing plant cost will definitely be more expensive than a plant for refined coconut oil. Virgin oils also tend to have a shorter shelf life. But given growing awareness about the many health benefits of virgin oils, they also command a premium in the market, making up for the increased investment in

Specifically designed for coconut processing from dehusking to coconut oil extracting, coconut husk processing and coconut shell processing. We have exported and installed our coconut machines in countries such as Indonesia, south africaia, Ghana, Papua New ethiopia, Fiji, Tahiti, Bahamas, Dominican Republic, Guyana, Ecuador and Mexico.

Coconut Oil Manufacturing Process Flowchart - Oil Expeller

- Usage: coconut oil

- Plate Type: Roll Transfer

- Color and Page: Multicolor

- Weight: 1000 kg

- Dimensions (L*W*H): 2300*2000*1300 mm

- Voltage: 220V , 50-60 Hz

Here are some business opportunities in coconut oil production business at many places around the world including India, Indonesia, Philippines, south africaia and Africa. Equipment & Machinery for starting Coconut oil Manufacturing business: Here are the important coconut oil manufacturing plant machines you need to start an oil manufacturing business:

The Virgin Coconut Oil Extraction process Coconut oil has long been considered a superfood because its unique blend of fatty acids provides multiple health benefits such as heart health, improved cognitive function, and weight loss. Virgin Coconut Oil (VCO) is extracted from the fresh and mature kernel of coconuts.

edible and cooking oil refinery plant in ethiopia

- Type: cooking oil extraction machine

- Production capacity: 40-600 kg/h

- Dimension (L*W*H): Depends on different model

- Voltage: 380 V/50 HZ/Three-phase

- Weight: Depends on different model

- Main components: Motor

Which edible oil plant has the highest oil content? Oil-seed camellia, oil palm, olive, and coconut ( Cocos nucifera) are the four well-known woody edible oil plants in the world, as they possess a high oil content. Among bulk herbaceous edible oils, the unsaturated fatty acids (UFAs) are the highest, approaching 80%, in peanut oil and rapeseed

Ernestine and Mungo started their coconut oil processing plant at Kanudi in Port Moresby in June 2015, buying copra from local farmers along the coastal villages in the Abau District of the Central Province, about a five-hour drive from the capital.

Virgin Coconut Oil (VCO) Extraction Plant - Oil Expeller

- Raw Material: coconut

- Production capacity: 1t/day-1t/hour

- Dimension (L*W*H): 800* 900*1050mm

- Voltage: 220V/50HZ 110V/60HZ

- Weight: 550 KG

- Main components: Engine oil

Machinery & Equipment required to setup a Virgin Coconut Oil Mill Plant. The requirement of VCO Mill Machinery and equipment usually depends on the different aspects such as processing raw materials, required pressing capacity, production cost budget and other detailed information.

The journey of coconut oil production progresses with the heating of either the freshly extracted coconut milk or the dried coconut meat known as copra. In the wet mill method, the coconut milk is gently heated, allowing the lighter oil molecules to separate and rise to the top, a process that can be enhanced by fermentation or other separation