FFB (Fresh Fruit Bunch) of Oil Palm into CPO (Crude Palm Oil

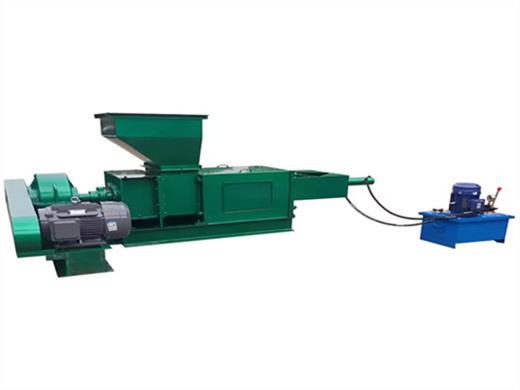

- Type: coconut oil milling machine

- Usage/Application: coconut, copra

- Warranty: One year

- Structure: Horizontal

- Appearance: Uniaxial

- Voltage: 380V, 380V

- Press series: Third, Second

- Country: nigeria

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, where a mill commonly handles 2.5 to 150 MT per hour of FFB. The quality of crude palm oil depends on the care taken after harvesting, particularly in the handling of the FFBs and the process adopted.

Oil Palm Plantation & Milling - Wilmar International

- Type: coconut oil processing machine

- Voltage: 380V

- Power (W): 20KW

- Certification: CE,BV,ISO9001

- Weight: 5500 KG

- Dimension (L*W*H): 2200*1600*2150 mm

As the oil palm continues to mature, its yield increases and reaches peak production in years seven to 18 before gradually decreasing thereafter. The typical commercial lifespan of an oil palm is approximately 25 years. Fully mature oil palms produce 18 to 30 metric tonnes of fresh fruit bunches (FFB) per hectare.

Empty Fruit Bunch (EFB) is the bio-mass of palm oil milling process, this biomass material can be used for energy generation, composting, mulching, pelletizing, etc. As the biomass pellet market booming these years, to convert the EFB into biomass pellets have been get the nod by the oil plant owners and the pellet market. EFB Shredder

palm oil line

- Usage: coconut oil

- Voltage: 230-380-430

- Power (W): 40kw/h

- Certification: CE and ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 20m*16m*15m

BTMA Machinery can offer you the BEST customized palm oil processing solutions for both fresh fruit bunch and palm kernel/nut. With years of experience in oil extraction and refinery filed, we are capable of turnkey oil mill plant construction, including process design, oil mill machinery manufacture, plant layout, installation and debugging

After harvesting, fresh fruit bunches must be transported to palm oil mills for processing within 48 hours to prevent palm fruits rancidity from affecting the quality of palm oil. The palm oil milling process involves sterilizing the palm fruits, threshing the palm fruits from the fresh fruit bunches, digestering palm fruits, pressing palm

FRESH FRUIT BUNCHES - Palm Oil Process - The Principle

- Type: cooking oil extraction machine

- Voltage: 220 V/380 V

- Main components: pressure vessel, pump, PLC

- Weight: 500 KG

- Type of oil: cooking Oil, essential oil

- Work process: collect material, add water, heat the still, filter the collected oil

24.01 The fresh fruit bunches are harvested and collected from the fields and transported to the mill by a variety of types and sizes of vehicles. These may include tractor-trailer operations, trucks fitted with side or rear tipping bins, hand loading or net loading of F.F.B. etc.

In general, palm oil milling machine is made up of sterilization,threhsing,digesting & pressing and clarification. Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, whereby a palm oil milling machine commonly handles 60 to 100 mt per hour of FFB. The palm oil mill plant of today is based predominantly on concepts

Palm oil production line | Palm oil mill - Huatai Oil Machinery

- Raw Material: coconut

- Voltage: 220V/110V

- Dimension (L*W*H) : 440L*300W*780Hmm

- Power: 120W

- Weight: 45kG

- Fields of Machinery function: cold pressing of oranges/citrus<br /Raw material: Fruit

Complete palm oil production process in large scale palm oil factory, Fresh fruit bunches (FFB) of oil palm after the fruit is harvested, it is processed in a palm oil mill, where the FFB is sterilized, digested, and pressed to extract palm oil. The extracted oil is then clarified and being sent for crude palm oil refinery plant, fractionation

Fresh Fruit Bunches (FFBs) are dense clusters of oil palm fruits, each containing 800–2,000 fruits, crucial for palm oil and kernel oil production. FFB development begins 24–30 months after planting, with pollination transforming female inflorescences into fruit bunches; proper timing ensures optimal oil content and quality.