Seed Oil Press Machines for Sale-Industrial Oil Press

- Type: cottonseed oil press

- Usage/Application: cottonseed

- Production capacity: 200 kg/h

- Voltage: 220 V

- Main components: Motor

- Weight: 100 kg

- Dimension (L*W*H): 375 * 160 * 275 (mm)

- Country: afghanistan

Cottonseed Oil Extraction Plant; Canola Oil Processing Plant; Coconut Oil Plant; 50T/D Edible Oil Production Plant; 30T/D Edible Oil Production Plant; 10-20T/D Edible Oil Production Line; 1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Capacity: 300 kg/h

- Dimension (L*W*H): 3255*985*1600

- Key selling points: Automatic

- Warranty: 1 year

- Weight: 100 KG

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Oil expeller machine is the soul equipment of the pressing process, it can be divided into small oil press and high capacity oil press according to its capacity. The top features of cotton seed oil expeller machine are based on the traditional product but include a variety of enhancements, implemented after-in-depth research on cotton seed oil

Cotton Seed Oil Press, Professional Oil Press Manufacturers

- Usage: cottonseed oil

- Voltage: 220 V/380 V/440 V

- Power (W): 18.5 KW/T

- Certification: ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 48m *12M*15M(30TPD)

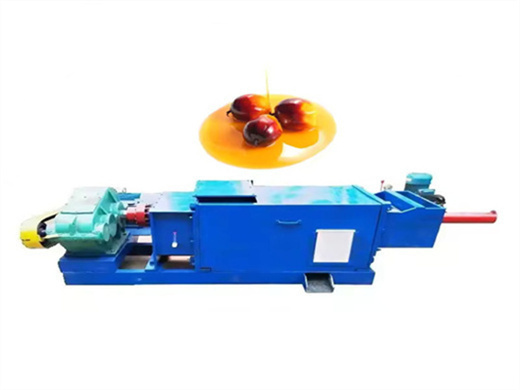

The 6yl screw seed oil press is a mini oil extraction plant that has gained great popularity in the global cottonseed oil extraction market. It is a versatile machine that can extract oil from various oil plants, such as cotton seeds, coconut, soybean seeds, peanut kernels, rapeseeds, and more.

Established in 2004, Mitsun Engineering is an exporter and manufacturer of engineering machinery such as Oil Expellers, Cottonseed Oil Expeller, Cotton Seed Expeller, Seed Cleaning Machinery. Our company has the capability to supply various types of machines as per the drawings of the clients and their specific requirements.

Factory Price Cotton Seed Oil Mill Machine for Sales | ABC

- Type: cooking oil extraction machine

- Production capacity: 7.2 t/24 h

- Dimension (L*W*H): 2100mmx1500mmx1650mm

- Voltage: 380 V

- Weight: 1700 KG

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, others, motor, cooking oil processing machine

Cotton Seed Oil Processing Machine (1~20T/D) Different from traditional screw oil press, our cotton seed oil machine is available with heating device. Therefore, you have the choice to save preheating time of the machine itself. More importantly, it can greatly improve the oil output as well as quality of crude cotton seed oil.

Cottonseed contains a kind of glyhol that is harmful to the human body. Whether it is squeezing or leaching cottonseed oil, it must be must be refined. Dingsheng Machine provides three types of cottonseed oil refining equipment: batch refining equipment, semi-continuous refining equipment of cottonseed oil, and full continuous refining equipment.

Cottonseed Oil Extraction Plant

- Raw Material: cottonseed oil

- Production capacity: 5TPD

- Weight: 1800 KG

- Voltage: 380 V

- Main components: Motor

- Oil type: Cooking oil

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.