BEST Cottonseed Oil Mill Machinery with Cheap Price

- Type: cottonseed oil press machine

- Usage/Application: cottonseed

- Production capacity: 16-18 TPD

- Voltage: 50 HP

- Main components: motor, bearing, gearbox

- Weight: 10000 KG

- Dimension (L*W*H): 3505 t1820t1981

- Country: indonesia

Wide Application of Cotton Seed Oil. Cottonseed oil is an extracted from the seeds of different cotton plants. These plants are mainly grown for cotton fiber, animal feed or oil. They have the same structure as those of sunflower seeds. Cottonseed oil is of light golden color with mild taste, but generally the color of the oil depends on the

Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Production capacity: 1t/day-1t/hour-100%

- Voltage: 220V/380V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

- Weight: 2580 KG

- Dimension (L*W) *H): Based in specifications

The solvent extraction process is to use the organic solvent to extract oil from the oil seeds, the press process is to use the mechanical pressure to press the oil from the oil seeds. The two different points between "pressing process" and "solvent extraction process" are the oil yield and the cost. When taking the pressing process, the

Cottonseed oil is classified as a kind of vegetable oil. It is extracted from the cotton plant, or more accurately from the seeds, and is generally used for cooking. Seed oils are preferred for diets that require lowered intakes of saturated fats.

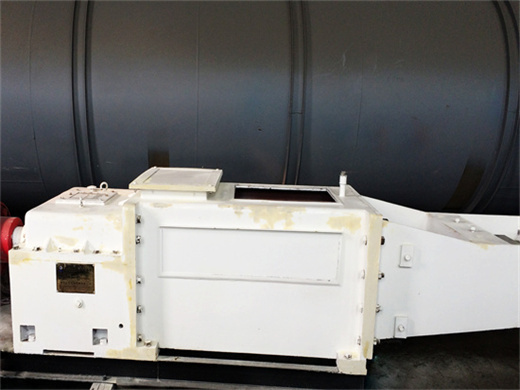

Cottonseed Oil Expeller / Extraction Machine Manufacturers

- Usage: cottonseed oil

- New and latest technology

- Production capacity: 100%, 10TPD -100TPD raw material

- Dimension (L*W*H): 2000x1400x1850mm

- Power (W): 5.5-15.5 kw

- Voltage: local voltage

The oil drip through small openings that do not allow seed fiber solids to pass through. Afterward, the pressed seeds are formed into a hardened cake, which is removed from the machine. Oil expeller machine is the soul equipment of the pressing process, it can be divided into small oil press and high capacity oil press according to its capacity

Improve the Economic Benefits of your Oil Mill Plant: To extract more oil from the cotton seed cake, soybean seed cake etc., (After extracting, the oil content in cotton seed meal can reach to 1%. ) Normally, after mechanical oil pressing process, the oil content in oil cake is around 8-13%, through our solvent extracting equipment, you can get about 7% more oil. And this modulator is suit for these customer:

Cotton Seed Oil Expeller for Sale|Premium Quality & Low Cost

- Type: cooking oil extraction machine

- Production capacity: 200-300kg/h

- Dimension (L*W*H): 2300*1300*1700(mm )

- Voltage: 220/380V

- Weight: 1420 KG

- Main components: Motor

We supply a great number of seed oil making machines including cotton seed oil expeller and automatic oil press for other plant seeds. We also offer turnkey solutions for complete set of oil mill plant, capacity ranging from 1 TPD to 6000TPD. Feel free to tell us your oil manufacturing needs and we will help you make the best plan!

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

Cottonseed Oil Press Oil Extraction Oil Refinery Plant

- Raw Material: cottonseed oil

- Production capacity: 10T-3000T/D

- Power (W): 18.5 KW

- Voltage: 380V

- Dimension (L*W*H): According to capacity

- Weight: According to capacity

2. cottonseed oil pre-press→ cottonseed oil extraction→cottonseed oil refinery. Normally for input capacity more than 20 tons per day, it's better to adopt the second Cottonseed Oil Processing Plant processing method with better cost performance.

The color is darker red than other oils. Only refined cottonseed oil can be consumed by humans. Siwei Group can provide full range of cottonseed oil solutions according to your needs, including site planning, engineering design, equipment manufacturing, installation and commissioning, as well as oil plant expansion and upgrades, etc.