oil solvent extraction manufacturers in ethiopia

- Type: soybean oil extraction machine

- Usage/Application: soybean

- Production capacity: 100% oil processing production line

- Voltage: Local voltage

- Weight: 30 tons

- Dimension (L*W* H): 2400x1500x1950 mm

- Power (W): Depends on capacity

- Country: ethiopia

The composition, extraction, analysis, bioactivities In contrast, ultrasound-assisted extraction is more suitable for large-scale production and has better development and application potential, it could significantly increase the yield of flaxseed oil by 11.5%, and the extraction rate of PUFAs by 68.12% (Ranveer, Gutte, & Sahoo, 2015; Long et

commercial big soybean oil extraction plant in ethiopia

- Type: soybean oil processing machine

- Voltage: 380V/50HZ

- Dimension (L*W*H): 5000x2580x2700mm

- Oil type: cooking oil, tung seed, sunflower

- Main components: Box of changes

- Weight: 8000 KG

The extraction process uses hexane or other solvents to wash the soybean oil from the prepared soybean flakes. The design of the equipment varies so that Crown can optimize the amount of solvent and bed depth needed to efficiently wash the flakes, the contact time of the solvent and flakes, and the power and utilities needed to run the

This fully automated extraction system uses very little solvent at elevated temperature and pressure and is able to run several queued experiments at programmed conditions. To rely on the results from ASE of soybean oil using green solvents, the hot-ball model was used as a validating tool. The hot-ball model gives a theoretical extraction profile

The Ultimate Guide of Soybean Oil Extraction Methods

- Usage: soybean oil

- Production capacity: 10T-3000T/D

- Voltage:380V

- Weight: According to Capacity

- Dimension (L*W*H): According to capacity

- Power (W): Capacity

Crude soybean oil needs to be refined before it can be sold or eaten. Soybean Oil Extraction Technology illustration. Usually, when the processing capacity of oilseeds is more than 20 tons/day, the extraction methods can be selected to produce soybean oil, which can reduce the production cost of soybean oil and obtain more profits.

If yes, join us to unveil the fascinating soybean oil extraction process. Have you ever wondered how modest soybean seeds become nutritious and delectable edible oils? .gatsby-image-wrapper noscript [data-main-image]{opacity:1!important}.gatsby-image-wrapper [data-placeholder-image]{opacity:0!important}

Soybean Oil Extraction Plant Project

- Type: cooking oil extraction machine

- Production capacity: 100TPD castor oil plant

- Power (W): depends on capacity

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

Choose a Strong Soybean Oil Extraction Equipment Manufacturer. Powerful soybean oil extraction equipment manufacturers can not only provide quality-guaranteed equipment, but also customize soybean oil extraction plans and soybean oil processing plant equipment layouts for manufacturers to ensure the smooth operation of the factory.

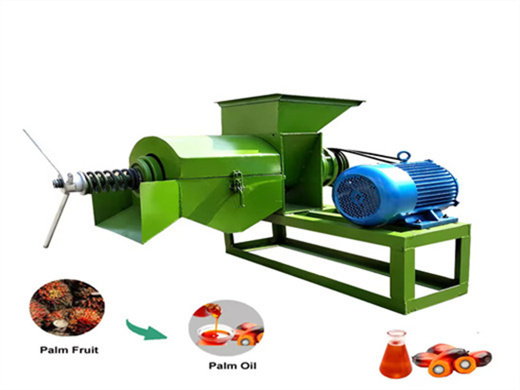

Oil Extractor. 6YL Series Spiral oil extractor is a new type of fully automatic combined cold pressing oil extractor developed according to market demand. This machine includes oil pressing system,automatic feeding system,vacuum oil filter system,beautiful appearance,easy to use,advanced performance. This machine is suitable for pressing peanut

Soybean oil production

- Raw Material: soybean

- Production capacity: 100%, 5T-200T per hour

- Power (W): 15 KW, According to capacity

- Voltage: 380V/50HZ, 380 V/440 V or local voltage

- Dimension (L*W*H): 1700*1100*1600mm, According to capacity

- Weight: 1200kg, According to capacity

Hi am interested to set up small scale industry of soybean oil extraction in east Africa So would you able to help with the latest techniques & machine list along with the quotation.If you understand of condition, I will very much thankful to you. Shugrishill@yahoo.co.uk my what's app number +254716162155 Shugri shill - 04/04/2018

Discover our state-of-the-art Soybean Solvent Extraction Plant designed for high-yield soybean oil production. This efficient and cost-effective facility utilizes advanced solvent extraction techniques to maximize oil extraction while providing valuable by-products like high protein soybean meal for animal feed.