Oil Press Plant Hcrank Oil Press in mozambique

- Type: palm oil press

- Usage/Application: palm fruit, palm kernel

- Production capacity: 30TPD~100TPD

- Voltage:220V/380V

- Weight: depends on mode

- Dimension (L*W*H):1610x615x1260mm

- Power (W) : 22kw

- Country: mozambique

Oil Press Machine. The large oil press machine is a continuous oil expeller which is suitable for preliminary pressing-solvent extracting press or twice pressing process in small and medium-sized oil plant, and used to handle with oil seeds such as rapeseed, peanut, sunflower, and cottonseed kernels. Production Capacity: 1-15tph. CONSULT.

Palm Oil Pressing Machine (Oil Extraction)

- Type: palm oil processing machine

- Raw material: Vegetable seed

- Function: Pressing oilseeds to obtain crude oil

- Machine Accessories: Sheller, Sheller, Toaster Machine, Press, Filter

- Spare parts: Worms, Rods, Cake Output Ring

- Advantage : High quality material, high oil production rate

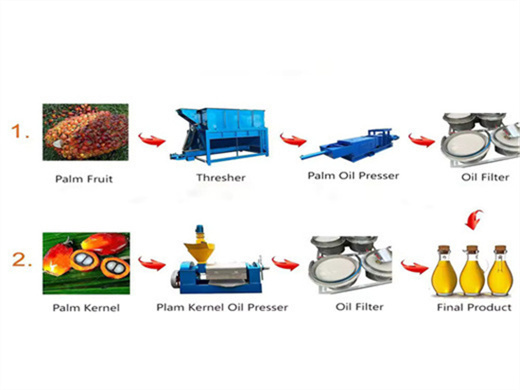

After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine. Besides, nuts and fibre or press cake will also be discharged as palm oil pressing residues. Palm Oil Pressing Machine (Oil Extraction)

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

palm oil line

- Usage: palm oil

- Voltage: 380 V

- Power (W): Standard

- Certification: CE,ISO

- Weight: standard

- Dimension (L*W*H): standard

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Digester Machine. The fruits are then digested in the digester.

Made In Palm Kernel Oil Extractor in mozambique

- Type: cooking oil extraction machine

- Production capacity: 200 TPD cooking oil mill

- Power (W): depends on capacity

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 5432*2636*2345

- Weight: 850 KG

QIE Machinery has been the industry of pam oil machinery manufacturing for at least two decades. After years of development, the Palm Oil Processing Machine we supply is suitable for industrial production, commercial business and farm use. Please contact us to get FREE customized project plant for your palm oil mill plant.

Our Automatic double-shaft palm kernel oil press machine is designed to meet the needs of modern palm kernel oil production, with capacities ranging from 10 TPD to 100 TPD. It features a large processing capacity, high oil yield, and long service life.

The anatomy of a commercial palm kernel oil press machine

- Raw Material: palm

- Production capacity: 1T/D-500T/D

- Dimension (L*W*H): 30x12x10m

- Voltage: 380v

- Weight: 50000 KG

- Main components: motor, pressure vessel, pump, PLC, motor, gearbox

Commercial palm kernel oil press machines have a built-in heating system to pre-treat the palm kernels, thereby improving the efficiency of palm kernel oil extraction. In addition, the precise temperature control ensures that the palm kernel oil retains its natural flavor and nutritional value, meeting consumer expectations for oil quality.

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.