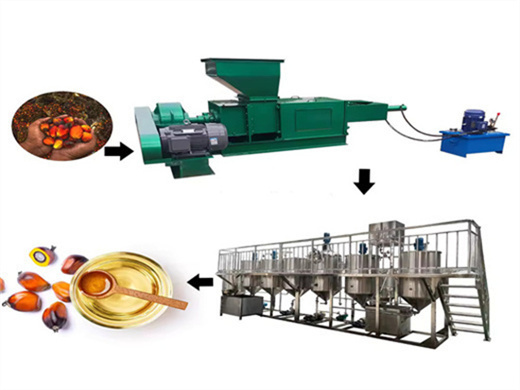

Palm Oil Production Line. Tailor-made Palm Oil Mill Plant

- Type: palm oil refinery plant

- Usage/Application: palm fruit, palm kernel

- Dimension (L*W*H): 1121*1602*1600 mm

- Weight: 400kgs

- Machinery function: Shape sorter, Color sorter

- Machinery capacity: 300-3000kgs per hour

- Voltage: 210-240v/50-60Hz

- Country: ghana

The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

Small Scale Palm Oil Mill Plant, Equipmentfor 1-20t/d Production

- Type: palm oil refinery machine

- Production capacity: 100-1000 kg/h

- Voltage: 220 V/110 V

- Main components: motor, gear

- Weight: 23 KG

- Dimension (L*W*H): 560*200 * 380 mm

One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory. Main Processing Equipments for Crude Palm Oil Mill Plant. The main equipment for small palm oil mill is palm fruits cooking and sterilizing tank, FFB Stripper and screw palm oil press machine

During the crude oil chemical refining process, the FFA will be removed and the neutralized crude oil and soap stock will be produced. And the soap stock will be separated from oil by using of high-speed separator. And the color pigments and the metal ions will be removed from the neutralized oil. If the crude oil contains high carotene, high FFA (more than 5% ) and relative low phosphatides, it will be great to have the chemical refining process to reduce the refining losses and the operation costs.

Physical and Chemical Process in Palm Oil Refining Plant

- Usage: palm oil

- Production capacity: 400-500 kg/h

- Voltage: 220V/380V, 220V/380V

- Warranty: 1 year, 1 year

- Weight: 850 KG

- Dimension (L*W*H ) : 2010*800*1380mm

Batch type is the ideal choice for mini and small sized production (1-20TPD), while the latter two are normally designed for middle-large size production line (10-50TPD). (Read more: Comparation of Batch Refinery, Semi-continuous Refinery and Continuous Refinery Plant) Palm Oil Physical Refining Plant

Palm oil processing. Alfa Laval has worked alongside palm oil producers since the earliest days of the industry. More than 50 years’ experience has gone into smart palm oil processing solutions for the entire supply chain – milling, POME management, refining and more.

Palm Oil Processing Production Line

- Type: cooking oil refining machine

- Production capacity: high

- Dimension (L*W*H): customization

- Voltage: 220V/380V

- Weight: 1100 KG

- Main components: motor, pressure vessel, pump, gear, bearing, motor, gearbox

Palm oil processing and palm oil mill Palm oil is an edible vegetable oil derived from the mesocarp (reddish pulp) of the fruit of the oil palms. It is naturally reddish in color because of a high beta-carotene content. Palm mesocarp oil is 49% saturated, while palm kernel oil is 81% saturated fats.

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Complete Palm Oil Mill Plant Layout Design

- Raw Material: palm

- Application area: cooking oil, oilseeds, etc.

- Delivery time: 25-60 days

- Payment terms: T/T 40% by advance, balance paid

- Package term: in container or according to customer

- Capacity: according to customer request

Palm Oil Mill Plant Layout Design. Palm oil production processes are completed in the palm oil processing plant. The layout design of palm oil processing factory is very important to increase the oil production capacity and lower the operational cost. The requirements for palm oil mill factory designing includes. Meet the Requirements of Palm

A palm oil fractionation plant will be a good choice. Henan Hongde palm oil fractionation plant adopts advanced crystallization equipment, filtration equipment, and accurate temperature auto-control software to separate palm olein and palm stearin which can get different melting-point fractionation products, including 18℃, 24℃, 32℃, etc.