Processing - Wilmar International

- Type: soybean oil processing plant

- Usage/Application: soybean

- Voltage: 230-380-430

- Power (W): 40kw/h

- Machinery oil loss: less than 5%

- Weight: 50 tons

- Dimension (L*W*H): 50m*30m*15m

- Country: lagos

Our edible oils are derived from refining crude palm oil, which are obtained from both our own plantations and third-party suppliers, as well as a wide range of oilseeds including soybean, rapeseed, groundnut, sunflower seed, sesame seed and cotton seed. From refining crude palm oil, we produce Refined, Bleached and Deodorised (RBD) palm oil

Small / Big Scale Soybean Oil Processing Plant - Oil Mill Plant

- Type: soybean oil processing machine

- Production capacity: according to capacity

- Voltage: 380V or 440 V

- Weight: according to capacity

- Dimension (L*W*H): according to capacity

- Power ( W): according to capacity

The following pictures shows some of the soybean oil processing plants. Soybean oil is an edible oil with a light and clean flavor that is commonly used for cooking. The oil is 60% polyunsaturated fat and 24% monounsaturated fat, according to the National Soybean Research Laboratory, making it a heart-healthy oil. Soybean oil is extracted by

From the raw seed through all stages of processing, we provide a complete solution for the oilseed processing industry. The most common seeds include soybean, canola/rapeseed, sunflower, palm and corn. If you have another seed that contains oil, we can customize equipment just for you. We’ll take the guesswork out of processing.

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Usage: soybean oil

- Main components: Motor

- Power: 3KW

- Control mode: Automatic

- Dimension (L*W*H): 75*75 *95cm

- Weight: 150 kg

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

Capacity Range: Ideal for soybean oil mill plants with a capacity of up to 100 tons per day (TPD). Mechanical pressing equipment is generally more compact and requires a lower initial investment, making it suitable for small to medium-scale soybean oil mill plants. High Oil Content Soybeans:

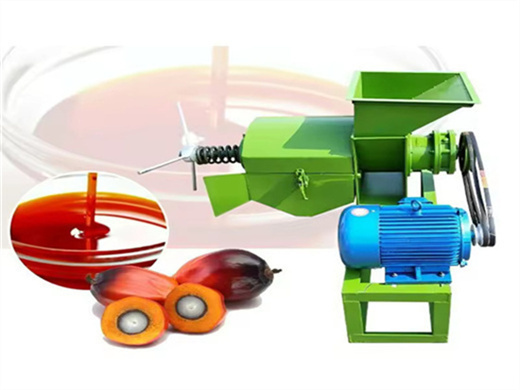

Hot Sell Plam Seeds Oil Processing Plant With in lagos

- Type: cooking oil extraction machine

- Production capacity: 200kg/h-2000kg/h-100%

- Dimension (L*W*H): 1055 *805*345mm

- Voltage: 220V/50HZ three-phase

- Weight: 27.1 kg

- Main components: Motor

PalmElit supplies CIRAD® oil palm seeds. The planting material we market is the outcome of stringent scientific research conducted by PalmElit breeders in several research partnerships. Your choice of planting material type and different commercial categories of CIRAD® seeds, along with the form purchased, needs to be based on

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil.

Oilseed Processing - NOPA

- Raw Material: soybean

- Production capacity: 1-2000TPD

- Power (W): 7.5 kW

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

Oilseeds such as soybean, canola, flaxseed, safflower seed, and sunflower seed are processed to create value added products for food, feed, fuel, and industrial use products. Oilseed processing is done by solvent extraction. Multiple steps are taken to remove the hull, flake the meal, extract and refine the oil, and then process the remaining meal […]

Soybean seeds contain 18% to 20% oil. Normally soya bean seeds are not subjected to mechanical pressing but the entire oil is extracted after preparation of the seeds in the solvent and Soybean Extraction Plant. Preparation of soya bean seeds includes seed cleaning, destoning, cracking, husk separation (if required), cooking, flaking, expanding and drying Oil extraction, isolation of oil from