Seed Oil Press Machines for Sale-Industrial Oil Press

- Type: cottonseed oil press machine

- Usage/Application: cottonseed

- Production capacity: 20TPH~80TPH, 20TPH~80TPH

- Voltage: 380-440V

- Certification: ISO9001

- Dimension(L*W*H): 1200*400*900mm3, according to capacity

- Power(W): according to capacity

- Country: bangladesh

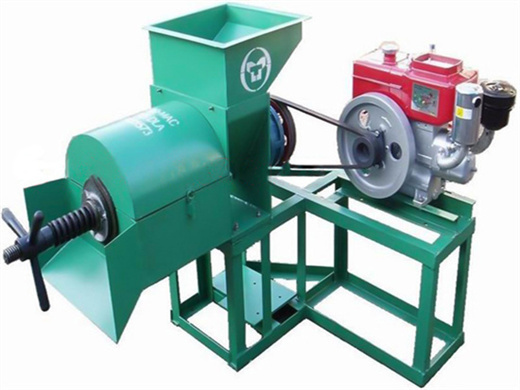

Use the electric motor or diesel as engine; high oil output,qualified oil,simple design and continuous operation;pressing various oil seeds,such as peanut, soybean,flax seed,cotton seed and so on;labor and energy saving because of the improved design;

Start Argan Oil Extraction Business with Reliable Oil Mill

- Type: cottonseed oil processing machine

- Production capacity: 250~270 kg/h

- Voltage: 220 V

- Working temperature: Water: 50-90°C Alcohol: 40-80°C

- Main components: container a pressure, PLC, engine oil Extraction volume (m³): 0.1 -0.5

- Weight: 800 KG

The following are the common types of argan oil processing machines: Small Scle Equipment Unit of Argan Oil Extraction Machines. Small Oil Pressing Line: This is designed for those processing small amounts of oil and doesn't require lots of space. Vegetable seed oil press is the machine features a built-in screw-like device that squeezes the

A cold cotton seed oil press is an oil extraction machine that uses hydraulic oil to pressurize and transmit pressure through an oil pump. The cold-pressed cottonseed oil has good oil quality, high oil yield, does not generate temperature during the cold-pressing process, does not destroy the organic components of the oil, and contains fewer

Argan Oil Press Machines - Efficient & Durable Solutions

- Usage: cottonseed oil

- Production capacity: 5-500TPD

- Voltage: 380V or according to local voltage

- Weight: 1050 KG of cooking oil producing machinery

- Dimension (L*W*H): 430*230*350 of the cooking oil producing machinery

- Power (W): according to the capacity of the cooking oil producing machinery

Cooking Plam Oil Production Line/cold Press Virgin Coconut Oil Extraction Machine/canola Argan Olive Essential Oil Press Machine $1,800.00-2,000.00 Min. Order: 1 set

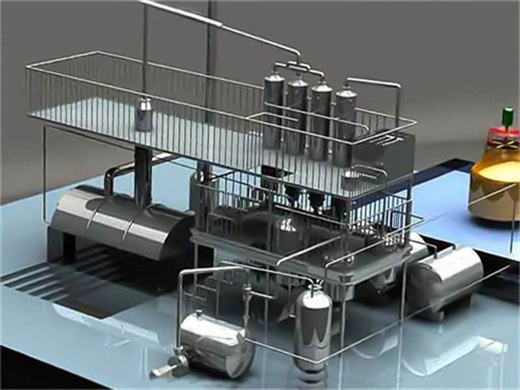

Cotton Seeds Oil Press Machine: Cottonseed oil extraction involves a series of steps, including delinting, dehulling, and flaking of the seeds. The flaked seeds are then subjected to high-pressure screw pressing to extract the oil, which is further refined to improve quality and stability.

Cotton Seed Oil Press, Professional Oil Press Manufacturers

- Type: cooking oil extraction machine

- Production capacity: according to capacity

- Dimension (L*W*H): according to capacity

- Voltage: 380 V or 440 V

- Weight: 1000 KG

- Main components:Motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

The 6yl screw seed oil press is a mini oil extraction plant that has gained great popularity in the global cottonseed oil extraction market. It is a versatile machine that can extract oil from various oil plants, such as cotton seeds, coconut, soybean seeds, peanut kernels, rapeseeds, and more.

The LG-ZY series argan oil extraction machine is a small hydraulic oil press which is the simplest operation in mechanical oil press, the highest oil output rate and the least number of replacement parts. It uses a fully automatic device, which takes only a few minutes from feeding to finished product at one time, and enjoys our lowest factory

Cotton Seed Oil Expeller for Sale|Premium Quality & Low Cost

- Raw Material: cottonseed oil

- Production capacity: 200kg/h-2000kg/h

- Power: depends on capacity

- Voltage: 220V/380V

- Dimension (L*W*H): depends on capacity

- Weight: depends on capacity

We supply a great number of seed oil making machines including cotton seed oil expeller and automatic oil press for other plant seeds. We also offer turnkey solutions for complete set of oil mill plant, capacity ranging from 1 TPD to 6000TPD. Feel free to tell us your oil manufacturing needs and we will help you make the best plan!

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.