milling machine for palm oil 4 ton in lusaka

- Type: palm oil expeller machine

- Usage/Application: palm fruit, palm kernel

- Voltage: 380v

- Dimension (L*W*H): 40HQ

- Main components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Motor, Gearbox

- Warranty: More than 5 years

- Weight: 3000 KG

- Country: lusaka

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

Palm Oil Machine - Palm Oil Production Line

- Type: palm oil processing machine

- Product capacity: 30-50 kg/H

- Raw material: Vegetable seed

- Weight: 220kg

- Size: 880*440*770mm

- English Operation Manual Book: Available

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Palm Oil Mill Plant - Hongde Palm Oil Production Line

- Usage: palm oil

- Voltage: 220 V, 380 V or other, according to your country

- Power (W): depends on capacity

- Certification: CE, ISO9001, BV for oil cake solvent extraction equipment

- Weight: depends on capacity

- Dimension (L*W*H): depends of capacity

If your palm fruit processing capacity is about 1-5 tons/hour, you can choose the standard configuration of palm oil mill plant line equipment, mainly by the fermentation tank, palm fruit extractor, mashing tank, palm oil press, rotary sieve and plate and frame filter and other equipment, the investment is generally from hundreds of thousands to millions, mostly suitable for medium-sized palm

The technical teams are ready to help you design and install the edible oil mill plant project based on your oilseed type, yield & budget. Various oil mill plants for manufacturing soybean oil, peanut oil, coconut oil, sesame oil, cottonseed oil, rapeseed oil, sunflower oil, corn germ oil, palm oil, and palm kernel oil, etc. have been exported & installed in various countries like India

palm kernel oil extruder machine for wholesales in lusaka

- Type: cooking oil extraction machine

- Customized: Customized

- Machine type: expeller of cooking oil

- Suit for: sunflower, soybean, peanut

- Capacity: 15-18t/D 25t-30t/D

- Motor power: 30kw-37kw

Hongde Machinery has been the industry of pam oil machinery manufacturing for at least two decades. After years of development, the Palm Oil Processing Machine we supply is suitable for industrial production, commercial business and farm use. Please contact us to get FREE customized project plant for your palm oil mill plant.

When choosing palm oil processing equipment, it must fully consider the palm oil production process technology requirements and various equipment specifications, performance, technical characteristics and use conditions. In the selection of equipment generally determine the type, and then consider the specifications. The following points should be noted when selecting equipment:

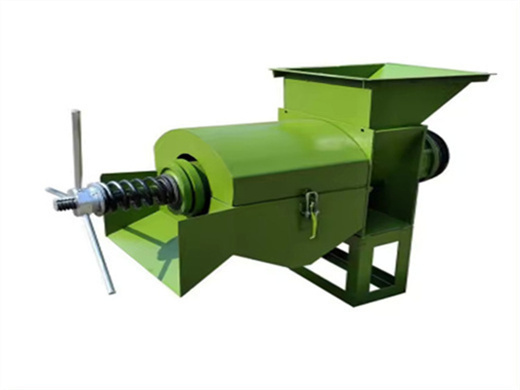

Palm Kernel Oil Manufacturing Process - Oil Expeller

- Raw Material: palm

- Production capacity: 100kg/h-1000kg/h

- Dimension (length x width x height): 1160*820* 1250 mm

- Voltage: 220V

- Weight: 240 kg

- Main components: motor, pump

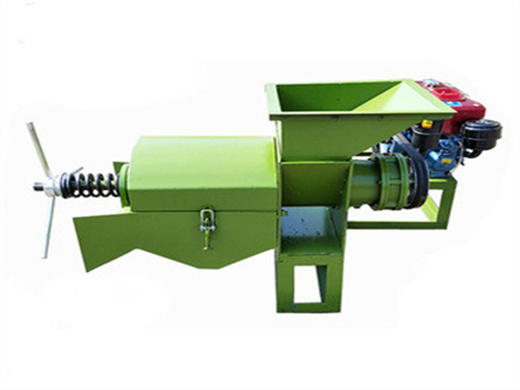

The cleaned Kernels are fed to a palm kernel oil expeller machine, which consists of a main shaft and worms, which rotates within a stationary perforated cylinder called a cage or barrel. As the main shaft turns, there is a decrease in volume resulting in pressure in the cage.

Multiple crystallisers are used in the series to maximise the use of filter through good planning. It is important to note that fractionation is quite modular technology and very often results in palm oil mill plant. Several water tanks (two to four), all at different temperatures, can be installed in order to maximise heat recuperation while keeping all cooling medium in a closed loop, but this can just as well be done with a single tank feeding chilled water to the crystallisers while steam is added to supply heat and normal cooling water is fed directly from a clean cooling tower. The fractional crystallisation of triglyceride oil is a slow process. The whole filtration and the squeezing operation can take from 30 to 90 minutes.