What is the basic principle of peanut oil solvent extraction?

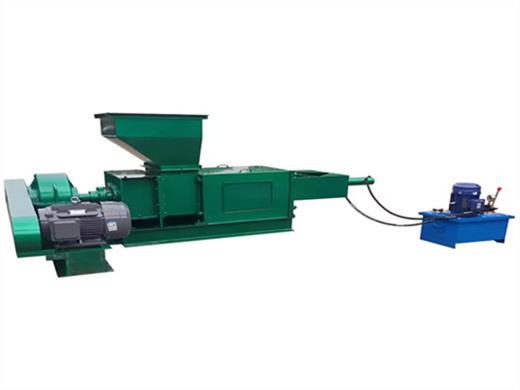

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 98%-100%

- Voltage: 380V/

- Weight: 950KG

- Dimension (L*W*H): 1950*1300*1900, according to capacity

- Power (W) : 5.5 ~ 18.5 KW

- Country: rwanda

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

A comprehensive insight into peanut: Chemical structure of

- Type: peanut oil processing machine

- Production capacity: 50 tons of oil per day

- Voltage: 380 V, adjustable

- Weight: adjustable

- Dimension (L*W*H): adjustable

- Power ( W): adjustable

Generally, the oil extraction efficiency can be increased by the roasted pretreatment due to the generation of permanent pores in the cell walls which allowed the movement of oil from them. 1: Conventional oil extraction: Cold press Soxhlet (n-hexane) Maceration (n-hexane) Using screw expeller T: 60 °C Time: 480 min T: 90 °C Time: 2880 min

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Usage: peanut oil

- Production capacity: 50-80Kg/h

- Voltage: 380V/50HZ

- Main components: motor, PLC, bearing

- Weight: 280 KG

- Dimension (L*W*H): 1400*860*1260mm

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

According to the FDA some hexane remains in the oil as “residue” and in 2009 the Cornucopia Institute fond that hexane residues are in Soybean, Canola, Peanut and other oils. Mazola and Crisco brands openly admit to using both GMO ingredients and hexane extraction in their processing.

Experimental Comparison between Ethanol and Hexane as

- Type: cooking oil extraction machine

- Production capacity: 100TPD palm oil machine

- Power (W): depends on capacity

- Voltage: 220V/380V/440V

- Dimension (L*W) *H): 5432*2636*2345

- Weight: 850 KG

Ethanol (Et) has been suggested as a substitute for hexane (Hx) for use in the extraction of oils from different oleaginous matrices. In this study, Et and Hx were used to extract the residual oil present in a peanut press cake (PPC). Certain variables, such as temperature, solid/solvent ratio and the number of contact stages, in the sequential cross-current extraction process were evaluated

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

Defatting and Defatted Peanuts: A Critical Review on Methods

- Raw Material: peanut

- Voltage: 380V

- Weight: 13500 KG

- Dimension (L*W*H): 5575*1806*2180

- Warranty: 1 Year

- Key Selling Points: Automatic

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated

Hexane has been widely used for oil extraction because of easy oil recovery, narrow boiling point (63–69 °C) and excellent solubilizing ability . In contrary, while in extraction and recovery processes, hexane is released into the environment that react with the pollutants to form ozone and photo chemicals [ 4 ].