Palm oil processing and production process

- Type: palm oil refinery plant

- Usage/Application: palm fruit, palm kernel

- Voltage: 380 V

- Power (W):Standard

- Certification:CE,ISO

- Weight:Standard

- Dimension (L*W*H):Standard

- Country: uganda

A full range of palm oil milling equipment, with everything you need for your oil room and (crude palm oil) CPO washing; Reliable palm oil refining process technologies with complete plant solutions for bleaching and deodorizing; Advancements to improve end-product quality while simultaneously boosting capacity, limiting loss and increasing yield

INDOPALM

- Type: palm oil refinery machine

- Production capacity: 6-8t/24h cooking oil mill machine

- Voltage: 220V/380V cooking oil press machine for sale

- Main components: PLC, press Hot Sale Guangzhou 6Yl-100 Small Screw Oil Making Machine

- Weight: 1400kg Guangzhou oil press

- Dimension (L*W*H): 2200*1650*1750mm

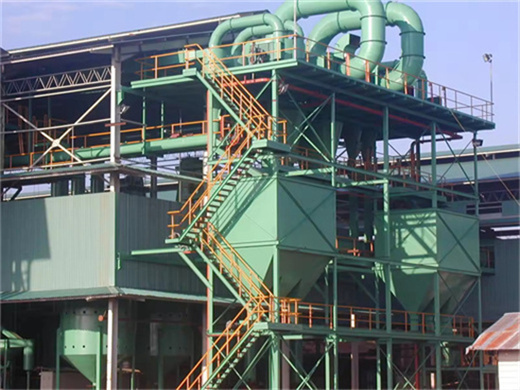

REFINING PLANT . 3400 MT/day and growing, Indopalm has one of the largest capacity plant, equipped with the latest Technology and fully automatic control system to produce the highest purity and quality standards of Palm Oil Products.

Hongde with advanced technology and comprehensive services is dedicated to providing high-quality solutions for palm oil refinery plant. info15@cnoilmachine.com 0086-159-3728-9608 0086-159-3728-9608 Home

Physical and Chemical Process in Palm Oil Refining Plant

- Usage: palm oil

- Production capacity: 5TPD--100%

- Voltage: 380v

- Main components: Motor, Pressure vessel, pump, PLC, others, gears, bearings, motors, gearboxes

- Weight: 2180 KG

- Dimension (length x width x height): 3200*2060*2950mm

According to the degree of automation, the refinery process can also be divided into Batch Refinery Plant, Semi-continuous Refinery Plant and Continuous Refinery Plant. Batch type is the ideal choice for mini and small sized production (1-20TPD), while the latter two are normally designed for middle-large size production line (10-50TPD).

Small scale palm oil refinery plant and large scale palm oil refinery plant. Depending on the level of automation, palm oil refinery plant can be divided into the following three categories: low cost mini palm oil refinery plant. Batch Refinery (1-20TPD)1TPD,2TPD, 3TPD, 5TPD,10TPD,15TPD, 20TPD, 30TPD.

Palm kernel oil refinery - palm oil refinery plant

- Type: cooking oil refining machine

- Production capacity: 50 Hz

- Dimension (length*width*height): actual

- Voltage: 380 V

- Weight: 700 KG

- Main components: Motor

The equipment required to refine crude palm kernel oil into edible oil is palm kernel oil refining machine. But according to the different of processing capacity, automation level, investment budget, the palm kernel oil refining machine can be divided into batch type, semi continuous and fully continuous.

Palm Oil Refinery is an important process in the palm oil mill plant to ensure the quality and safety of palm oil. It’s recommended to refine crude palm oil through our palm oil refining machines to get high-quality palm oil that is easy to store and can priced high. Refined palm oil can be packed and labeled for the local or global market

Complete Palm Oil Production Line

- Raw Material: palm

- Production capacity: 5TPD

- Dimension (L*W*H): 56*26.5*33cm

- Voltage: 220V/110V

- Weight: 13 KG

- Main components: Motor

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been rooted in grain and oil equipment manufacturing for 37+ years. It has a modern production base of 100,000 square meters, equipped with cutting-edge equipment such as laser cutting machines, fully automatic welding robots, CNC precision machining centers, and an annual production capacity of more than 200 large-scale edible oil

1-500TPD Palm Oil Fractionation Plant. Palm oil fractionation plant (1-500tpd) Heating section: In advance, the refined palm oil needs to be heated to about 60°C to turn the oil into a pure liquid state (crystallization).