palm kernel oil extracting machine in indonesia

- Type: palm kernel oil making machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 3-6 KG/hour

- Voltage: 220V/110V

- Function: Oilseed press

- Certification: CE

- Dimension (L*W*H): 350*320*160 MM <br /Weight: 6.6 KG

- Country: indonesia

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

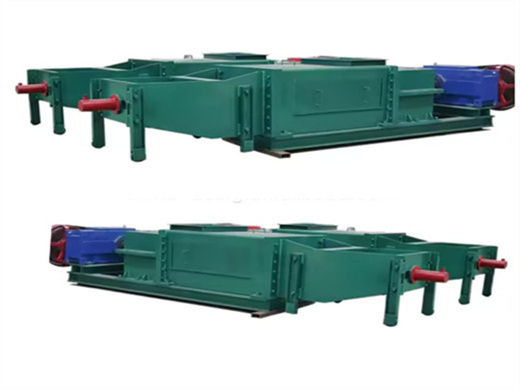

palm oil line

- Type: palm oil processing machine

- Voltage: 220/380/400V

- Power (W): 260KW

- Certification: CE&ISO&BV, ISO9001&BV&CE&TUV

- Weight: 60000KG

- Dimension (L*W*H): 15*12*12

There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

Key Features of an Effective Palm Kernel Oil Mill Machine. 1. High Extraction Rate One of the foremost considerations when selecting a palm kernel oil mill machine is its extraction rate. The best machines are designed to maximize oil yield while minimizing waste. Modern machines can achieve extraction rates of up to 95%, ensuring that

iso ce combined automatic cold palm oil press in indonesia

- Usage: palm oil

- Production capacity: 800 tons of oil per day

- Voltage: Adjustable

- Steel Moisture of finished food: ≤ 10-13% (adjustable)

- Residual solvent in finished food: ≤ 300PPM (qualified detonated experiment)

- Degree of oil: Grade 1

Supply turnkey palm oil pressing plant and all kinds of quality palm oil machines including palm oil press, palm oil expeller and filter with competitive price. Send an inquiry now and tell us your budget, situation and other requirements. Then we can guide you starting palm oil pressing and refinery business step by step.

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Palm Oil Mill Plant - HuaTai Palm Oil Production Line

- Type: cooking oil extraction machine

- Production capacity: 100% oil press machine

- Power (W): 5.5 ~ 18.5 KW

- Voltage: 220V/380V/440V

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Weight: 950KG

Pressing Process in palm oil mill The pressing process requires maximum extraction of palm oil from the pulp, but the kernels cannot be broken because the crushed palm kernel oil will contaminate the crude palm oil and affect the quality. Using two or more pressing processes can effectively reduce the cracking rate of nuts.

Huatai’s palm kernel oil pressing and extraction production line can flexibly adjust the process according to the characteristics of the palm kernel: For palm kernels with high shell content, the kernel-shell separation link is strengthened, and multi-stage vibrating screens and wind sorting devices are added to control the shell residue residue rate below 3%; If the moisture content of the

Palm Kernel and Palm Kernel Oil - Palm oil extraction machine

- Raw Material: palm

- Production capacity: 2-4kg/h

- Dimension (L*W*H): 450*180 *305 mm

- Voltage: 210V/110v

- Weight: 11kg

- Main components: Motor

In the business of investing in the construction of palm oil processing plant in Indonesia, the selection of the mill site is a crucial part of the whole project construction. This decision not only directly affects the progress of the factory construction and the scale of investment, but also has a significant impact on the local economy, environmental protection, agricultural development, and social benefits. Therefore, precise and careful location selection will play a decisive role in the long-term planning and sustainable development of the palm oil mill project.

2) Crude oil centrifugal filter: Quickly separate the pressed oil and pomace to obtain cleaner crude oil. 3) Palm kernel special oil pressing machine: Specially designed for palm kernels of different sizes, easy to clean and low maintenance cost. 3. Palm Oil Refining and fractionation equipment