Soybean Oil Making Machine

- Type: soybean oil extractor machine

- Usage/Application: soybean

- Production capacity: 18-250 KG/H, almost 1 t/day

- Voltage: 220 V/110 V/380 V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox changes

- Weight: 500 kg

- Dimension (L* W*H): 600*600*1500 mm

- Country: botswana

Benefits of Soybean Oil Making Machines 1. High Oil Yield: Modern soybean oil presses are designed to extract a high percentage of oil from the soybeans, improving overall profitability. 2. Efficient Production: The machines are built to operate efficiently, reducing wastage and ensuring a high-quality product with minimal energy consumption. 3.

Efficient Soybean Oil Extraction Machinery | High-Quality

- Type: soybean oil processing machine

- Production capacity: Depends

- Voltage: 220V/380V

- Dimension (L*W*H): according to capacity

- Weight: according to capacity

- Power (W): according to capacity

Soybean and similar oil crops Soybean: As the most common oil-pressing crop, soybean oil extraction machinery can efficiently extract its oil. These machines can handle soybeans of different varieties and qualities to meet different production needs. Soybean: Soybean is similar to soybean, and its oil content is also low, but soybean oil

Cooking oil industry is one of the most basic sectors for the developmen of human beings. There are many oilseeds that are suitable for cooking oil processing, like soybean, groundnut, palm kernel, sunflower seeds, cottonseeds, etc. Cooking oils are extracted by a series of oil production processes, the most common cooking oil extraction processes has:

Soybean Oil Extraction Machine - Buy Soybean Oil Extractor

- Usage: soybean oil

- Customized: Customized

- Capacity: 30-1000t/D

- Material: SUS304/316

- Warranty: 12 months

- Color: Red, White or Customized

Scientific soybean oil extraction design with lowest solvent addition. We adopts vacuum evaporation, and solvent soaking or spaying method to extract soybean crude oil from soybean with high oil yield and low residual oil in soybean meal.

Soybean Oil For Various Uses. Soybean oil is an edible oil with a neutral taste which is extracted from the soybean seeds with the help of soybean oil machine. It is mainly used for the purpose of cooking. This cooking oil is very healthy for our body as it is high in omega-3 fatty acids and polyunsaturated fats and low in saturated fats.

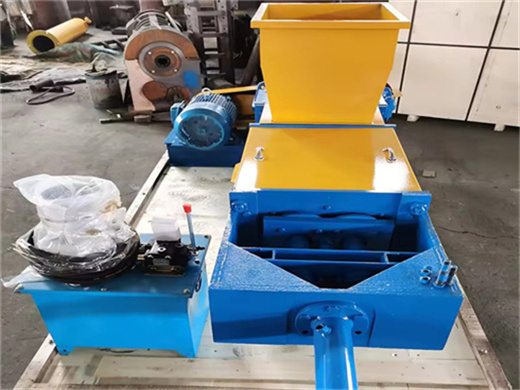

Soybean Oil Expeller Machine

- Type: cooking oil extraction machine

- Press Materials: Oil Crops

- Custom: Custom

- Press Series: Second

- Capacity: 1-1000 tons

- Advantage: Easy operation

The expeller machine applies mechanical pressure to crush and squeeze the oil from soybeans, and it is commonly used in both small and industrial-scale oil extraction plants. Working Principle of a Soybean Oil Expeller Machine 1. Soybean Seed Preparation: - The first step is cleaning the soybeans to remove impurities like dirt, stones, and dust.

The quality of pre-treatment directly contributes to the performance, longevity, and safe oil extraction of the oil press machine. Features of screw soybean oil press. The 6yl-95 screw soybean oil press machine is an advanced soybean oil extraction machine that is highly efficient, easy to operate, and suitable for mobile oil processing

Soybean Oil Extraction Plant, Soybean Oil Machinery

- Raw Material: soybean

- Raw material: Seeds

- Ingredient: Other , avocado

- Available supply quantity: 10000 kg

- Features: Skin revitalizer, dark circles, moisturizing, whitening

- Function: Facial care, hair care

The extraction process for soybean oil production can be classified into two main types: mechanical pressing and solvent extraction. Soybeans have a relatively low oil content, and solvent extraction using hexane typically yields around 19%, while mechanical pressing produces an oil yield of approximately 13%.

Extraction Efficiency: Look for suitable processes and machine known for their high extraction efficiency. Efficient extraction ensures optimal oil yield and reduces wastage. Processing Method: Consider the extraction method. Common methods include mechanical pressing, solvent extraction, or a combination of both.