Cottonseed Oil Processing Plant | Extraction Flow

- Type: cottonseed oil refinery plant

- Usage/Application: cottonseed

- Production capacity: over 90%

- Voltage: 220 V

- Production: 50-500 kg/h

- Weight : 1000 kg

- Dimension (L*W*H): 48x24x45cm

- Country: cameroon

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

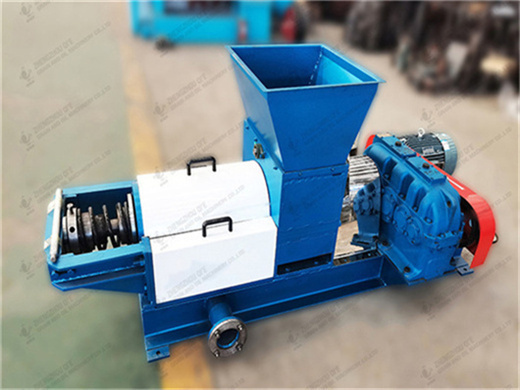

Cottonseed Oil Mill Plant

- Type: cottonseed oil refinery machine

- Production capacity: 5TPD-100TPD

- Voltage: 380V/50HZ

- Oil type: Cooking oil

- Main components: Motor

- Dimension (L*W*H): 1510*440*700mm<br / Weight: 350kg

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Units of Trade: Conversion rules in the global oil industry. Tonnes, barrels, cubic meters and gallons; Global Oil Logistics: Ships, Fleets and Tracing. Tips for Traders. History and modern methods of oil refining: from feedstock to petroleum products; The basis of a successful transaction: Correct document flow. Sample documents.

Cottonseed Oil Extraction Plant

- Usage: cottonseed oil

- Power source: Electric

- Voltage: 380v/50hz, 380v/50hz

- Dimension (L*W*H): 850* 880*1000 mm

- Weight: 260 KG

- Power: 1500, 1.5kw

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

Oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment. With the high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in large

Oil Mill Plant | Oil Mill Factory | 10-500 TPD

- Type: cooking oil refining machine

- Production capacity: according to capacity

- Power ( W): according to capacity

- Voltage: 380V or 440 V

- Dimension (L*W*H): according to capacity

- Weight: according to capacity

Complete quality certification: AGICO has been approved ISO 9001, CE-certified to provide turnkey project services to oil seed processing plants, oil extraction plants, oil refining plants, and related equipment. After-sales service: If you have any problems keeping your plant up and running, we provide service 24/7. We also conduct regular

For large cottonseed oil production lines with capacities of over 30 TPD, the solvent extraction method is usually adopted working together with cottonseed oil pre-press to maximize the oil yield. The large cottonseed oil production line includes a cottonseed pretreatment and pre-pressing workshop , a cottonseed cake solvent extraction workshop

Cottonseed Oil Processing - Oilmillmachinery.net

- Raw Material: cottonseed oil

- Production capacity: 4500 kg/hr

- Dimension (L*W*H): Length x width x height = 6 x 3.5 x 5.5

- Voltage: 415+-10% volts

- Weight: 650 KG

- Oil type: cooking oil

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

the highest extraction yield of cottonseed oil (CSO). The extraction e ffi ciency was measured based on the e ff ects of temperature, organic solvent (OS), extraction time and solvent:seed (s:s