Start an Automatic Groundnut Oil Processing Line

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Product Type: Fruit Oil

- Processing Type: Refined

- Packaging: Bulk, glass jar

- Cultivation Type: COMMON

- Refined Type: Fractionated Oil

- Country: bangladesh

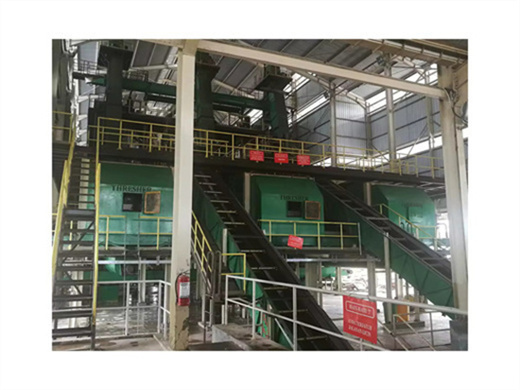

(Related Project: 10 ton/day Peanut Oil Mill Plant in lesotho) Small Crude Oil Refining Machine for Processing Cooking Oil. This is a mini physical refining plant which belongs to batch oil refinery unit which is commonly used in small scale edible oil refinery, the production capacity ranges from 1 tons per day to 20 tons per day.

What is the cost of mini soya bean oil processing plant

- Type: peanut oil processing machine

- Voltage: 380 V

- Dimension (length x width x height): 5000 x 2580 x 2700 mm

- Oil type: Cooking oil, Tung seed, Cooking, Sunflower

- Main components: Gearbox

- Weight: 8000 kg, 8000 kg

The main equipment of mini soya bean oil refinery plant. The small scale soya bean oil refinery plant includes degumming, deacidification, decolorization/bleaching and deodorization four processes. After processing, finally you can get high quality First Grade soya bean oil and sell it to the market with good price.

Peanut Oil Making is now profitable venture in edible oil processing industry around the world. And it features great export potential, especially in those countries that plant peanuts/ groundnuts, such as China, India, africa, the United States, Sudan, Myanmar, Chad, Cameroon and more. Before starting the business, it is necessary to get a clear understanding of peanut oil manufacturing process, machine, cost, requirement, market demands and more.

Mini Scale Soybean Oil Processing Plant for Small Business Plan

- Usage: peanut oil

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power (W) : 18.5KW

Benefits of Building a Mini Soybean Oil Mill Plant. First, this mini soybean oil plant is user-friendly and not labor-intensive. For your information, you can ably operate the plant with a workforce of two to three people only. The operating environment of the plant is safe. Secondly, you can set up the unit hassle-free.

Mini Oil Refinery Plant is the No.1 choice for small or medium scale oil mill plant to improve the oil quality and reduce the oil production cost. Here, we will help you gain the complete knowledge about edible oil refinery plant, including its functions, working principles, production process, setup cost, machines required and more.

How to Start Mini Soybean Oil Mill Plant | 1~30 Tons/Day

- Type: cooking oil extraction machine

- Production capacity: 400~600 kg/h

- Power (W): 18.5 kW

- Voltage: 220V/380V

- Dimension (L*W*H): 1500 *1600*2500mm

- Weight: 2000kg

1~30TPD Mini Soybean Oil Mill Plant. Mini Soybean Oil Mill Plant at Low Cost. Soybean oil processing requires a series automatic process. Normally, the basic process of mini soybean oil processing plant is cleaning, cooking, oil pressing, oil filtration or oil refining, etc.. Every process has the respective soybean oil processing equipment to

Soya bean Oil ProductionProcess & Equipment. Soya Bean Oil Production Process. The processing of oils and fats mainly has two methods: the pressing process for high oil content oil crops (normally 30% above), the solvent extraction for oil crops of low oil content. Oil pressing process may have 10% of oil residual in the raw materials, while

Have an Idea about the Mini Soya Oil Refinery Plan

- Raw Material: peanut

- Production capacity: 1-100T/D

- Power (W) : 20-50KW

- Voltage: 380V/440v

- Dimension (L*W*H): 2050*1350*2000mm

- Weight: 800kg

And, it is used not only for soya seeds but for rapeseed, cotton seeds, corn seeds, sesame seeds and peanut kernels as well. Do you intend to have an idea about the mini soya oil refinery plan? The mini soya oil refinery plan involves the following primary steps sequentially one by one. These are: 1. Cleaning the Soya Beans

1. Full automatic screw oil press with vacuum filtration, rapid purification and automatic temperature control technology; 2. The oil output rate is high, about 3% higher than that of ordinary hydraulic press, and the installation is convenient; 3. The oil has high purity and can be eaten directly after vacuum filtration; 4.