Efficient Sunflower Oil Milling Machine - Balancing Output

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 50-500 kg/h

- Voltage: 220v-240V

- Main components: Motor

- Weight: 10.5 KG

- Dimension (L*W*H): 46*22.5* 26 cm

- Country: afghanistan

It is commonly used in small to large-scale oil mills for the efficient extraction of sunflower oil. Key Features of a Sunflower Oil Milling Machine: 1. Multi-functional Processing: - Cleaning: Ensures seeds are free from impurities like dust, stones, and plant debris. - Dehulling: Removes the hard shell from the sunflower seeds to increase oil

Sunflower Oil Extraction Process, Methods – A Full Guide

- Type: sunflower oil processing machine

- Voltage: 380 V

- Power (W): Standard

- Certification: CE,ISO

- Weight: Standard

- Dimension (L*W*H): Standard

Cost of Sunflower oil extraction machine: Cost of automatic Sunflower oil extraction machine approximately, Rs 1.45 Lakh/Piece. Benefits of Sunflower oil. May enhance oral health. Sunflower oil is extremely useful for oil pulling. Sunflower oil reduces plaque-related gingivitis.

In the modern oil industry, they use chemical solvents (such as hexane) to extract sunflower oil, and refined by solvent extraction,degumming, neutralization, bleaching and other processes. Sunflower oil has high oil yield and high economic benefits, and the daily output can reach 300-3000 tons.

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

- Usage: sunflower oil

- Production capacity: 30-60 kg/h

- Voltage: 220 V 50 Hz

- Main components: Others

- Weight: 220 KG

- Dimension (L*W*H): 120*78*110 cm

Quality Control in Sunflower Oil Extraction. Quality control is essential to ensure that the sunflower oil extracted is of high quality and safe for consumption. We will discuss the various quality control measures that can be implemented during the sunflower oil extraction process, including testing for contaminants, oxidation, and rancidity.

There are two main types of sunflower seeds, oil sunflower seeds and edible sunflower seeds. The oil content of sunflower seeds is about 45%-54% (calculated as 50%), and the oil content of edible sunflower seeds is about 22%-35% (calculated as 30%). Among them, oil sunflower seeds are usually the main raw material to extract sunflower oil. Oil

Sunflower Seed Preparation and Oil Extraction - ResearchGate

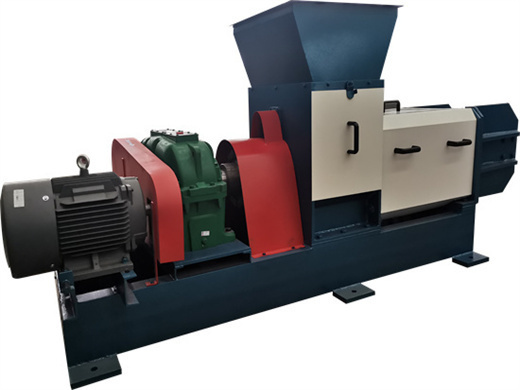

- Type: cooking oil extraction machine

- Production capacity: 10-160 kg/h

- Dimension (L*W*H): 700*800*780mm

- Voltage: 220v/380V

- Weight: 240 KG

- Main components: Motor, PLC

Sunflower seed processing focuses on extracting the oil contained, as it is the most valuable product, and used as high value oil in numerous food applications (Le Clef & Kemper, 2015).

1. High efficiency: Modern sunflower seed oil extraction machinery adopts advanced processes and technologies, which can significantly increase the oil extraction rate. The mechanical pressing process of the press is mature and can extract a large amount of oil in a short period of time while minimizing the waste of raw materials. 2.

Worldwide Sunflower Seed Processing - Shelling Machine

- Raw Material: sunflower

- Production capacity: depending on seeds

- Dimension (L*W*H): 43*29*21cm

- Voltage: customization

- Weight: 11 KG, 7 (KG)

- Main components: Motor

In 1716, the British got the success in oil extraction from sunflower seeds, and the sunflower seed oil had a worldwide attention from then on. The success of sunflower seed oil extraction promoted the research and extension of sunflowers’ varieties, however, it was not until the 19th century sunflowers were still taken as

Extracting sunflower oil requires specialized equipment that can efficiently process sunflower seeds while retaining the oil’s purity and nutritional value. This blog explores the essentials of sunflower oil extraction and how Andavar supports businesses in producing high-quality sunflower oil.