Sunflower Oil Extraction Process, Methods – A Full Guide

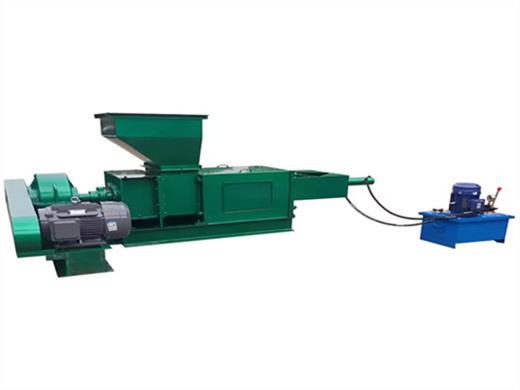

- Type: sunflower oil processing equipment

- Usage/Application: sunflower

- Production capacity: 30-450 kg/lot

- Voltage: 220 V/ 380V

- Warranty: 1 year

- Weight: 230 KG

- Dimension (L*W*H): 1200*800*1160mm

- Country: johannesburg

Cost of Sunflower oil extraction machine: Cost of automatic Sunflower oil extraction machine approximately, Rs 1.45 Lakh/Piece. Benefits of Sunflower oil. May enhance oral health. Sunflower oil is extremely useful for oil pulling. Sunflower oil reduces plaque-related gingivitis.

How is Sunflower Oil Processed?

- Type: sunflower oil processing machine

- Production capacity: 100% sesame seed oil mill

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W*H): Depends on its capacity

- Power (W): 10-50kw

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

Overall, making sunflower oil is a complex process that involves several steps. The quality of the oil depends on the quality of the seeds and the method of extraction used. Cold-pressed sunflower oil is generally regarded as the highest quality, as it retains all of its beneficial compounds.

From Seed to Oil: Unveiling the Sunflower Oil Extraction Process

- Usage: sunflower oil

- Production capacity: 100%

- Voltage: 220V, 380V

- Weight: 1600 kg

- Dimension (L*W*H): 2000*1650 *1500 mm

- Power (W): 11kw

Quality Control in Sunflower Oil Extraction. Quality control is essential to ensure that the sunflower oil extracted is of high quality and safe for consumption. We will discuss the various quality control measures that can be implemented during the sunflower oil extraction process, including testing for contaminants, oxidation, and rancidity.

The oil must be extracted to separate it from the solids using one of several processes. Three types of sunflower oil produced for cooking applications, which vary in oleic levels, are: NuSun, linoleic and high oleic. Oil-seed-type sunflower seeds are used for oil production rather than for common snack seeds.

Sunflower Oil Press & Oil Extraction Process - Site

- Type: cooking oil extraction machine

- Certification: ISO9001

- Voltage: 220V/380V

- Product Production capacity: 10 - 3000TPD

- Power (W): According to its capacity

- Dimension (L*W*H): depends on the mode

Sunflower oil can be extracted during the solvent extraction process using chemical solvents or by a sunflower oil press (screw press) used to squeeze the oil directly from sunflower seeds by crushing them. This method of cold-pressing sunflower seed oil under low-temperature conditions is a preferred method for those seeking an extraction

This process leaves two products: one, high quality, nutrient-dense oil which is transferred to the oil refining process; two, the remaining compressed oilseeds, also referred to as oil cake, which have some oil content left over in them – as you might’ve guessed, these move on to the solvent extraction step.

HOW IS SUNFLOWER OIL EXTRACTED? - Grainvest

- Raw Material: sunflower

- Production capacity:5t/h

- Dimension (length*width*height): 1000X538X1050mm

- Voltage: 380V

- Weight: 140 KG

- Main components: engine, others, gears, bearings, motor, gearbox

Sunflower oil production has the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extraction of crude oil from these seeds and then further refining the oil obtained before packaging. A volatile hydrocarbon like hexane is used as a solvent to extract the oil. Cleaning; De-hulling; Grinding; Pressing

The prepared sunflower oil seeds are passed over magnets to remove the trace metal before de-hulled; and passed the special cleaning machine to remove other foreignhavematters. 2. De-hulling (optional) Sunflower seeds from the oil-type contain about 20%-30% hulls that are sometimes removed before oil extraction