Hydraulic Oil Press for Making Cold P

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Production capacity: 2.5-3,500 kg/h

- Voltage: 200-240 V, 200-240 v

- Main components: motor, pressure vessel, pump

- Weight: 13 KG

- Dimension (L* W*H ): 48*25*41 cm

- Country: pakistan

Peanut oil or sesame oil production for example, the oil rate is 2%-3% higher than screw oil press. Therefore, seeing these you should know why screw oil press cannot replace hydraulic oil press. If you are interested to get detailed price list and customized cold oil extraction process, or need any guide on walnut oil production, almond oil

Advanced nut processing with the peanut oil press machine

- Type: peanut oil processing machine

- Customized: Customized

- Suit for: Sunflower, Soybean, Peanut

- Motor power: 30kw-37kw

- Capacity: 15-18t/D 25t -30t/D

- Type Machine size: Multifunctional edible oil mill

A peanut oil press machine is your gateway to a more efficient and cost-effective peanut oil production process. It’s a business production powerhouse that does more than just squeeze oil out of peanuts. It streamlines the entire process and results in a high-quality, accurate product The automatic peanut oil Press is a popular model.

With ULIMAC’s UM200 cold press oil machine you press homemade oil from all oil-rich seeds and nuts. Our UM200 oil press has high extraction efficiency and allows you to make your own natural oil. The UM200 cold press oil machine model is a new generation cold press used in oil extraction and processing plants to extract oil at a lower

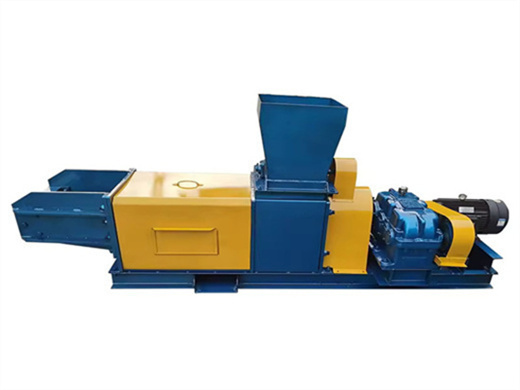

Fully Automatic Peanut Cold Oil Press Machine

- Usage: peanut oil

- Production capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850 mm

- Power (W): 7.5 kW

With its high oil yield and versatility, this machine is perfect for all types of food processing enterprises and oil mills, allowing you to stand out in a competitive market. Ideal for large-scale industrial production or small-scale family workshops, our equipment meets diverse customer needs and is the ideal choice for the future of oil

Also, careful study of the space used to produce cold press oil and the basic design of the cold oil press line has a great impact on the optimal and correct selection of equipment. In low capacity cold press oil production units, the cold press machine is the main tool, feeding the machine and transferring productions is manually

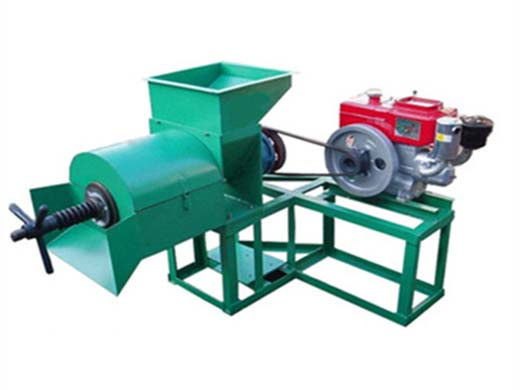

High-Efficiency Peanut Oil Extraction Machinery | Advanced

- Type: cooking oil extraction machine

- Production capacity: 40-90 KG/H

- Dimension (L*W*H): 850 x350 x570 mm

- Voltage: 220 V/380 V

- Weight: 320 kg

- Main components: Motor, Engine

Specialty and Boutique Production: For producers who focus on high-quality, peanut oil, cold press machines and small hydraulic presses are often the equipment of choice. These machines ensure that the oil retains its full flavor and nutritional profile, catering to the growing demand for premium, health-conscious products.

The Hydraulic Oil Press Machine is an advanced oil extraction solution designed for high-purity, cold-pressed oils. Ideal for small-scale oil production or specialty oil processing, this oil press machine ensures optimal oil yield while preserving the natural nutrients, flavor, and aroma of the raw material.

Cold Press Oil Machines | Oil Press Machine | Nut Butter Machine

- Raw Material: peanut

- Production capacity: 150-300 kg/h

- Dimension (L*W*H): 1900* 1200* 1600 mm

- Voltage: 220 V/380 V

- Weight: 1200 kg

- Main components: motor

With the Ulimac cold press oil machines, you can press oil from more than 100 seeds and nuts. With it’s easy to use performance and high production capacity, Ulimac cold press oil machines have many advantages over their rivals. The best cold press oil machines used in cold pressed oil production are produced by Ulimac.

They have Cold press machines at reasonable Cold Press Oil Machine Prices in the Indian market. Among the various items available from this well-known manufacturer are oil expellers , labeling machines, pizza ovens, pulverizer machines, filling machines, destoning machines, product coders, processing equipment for foodstuffs, and packaging