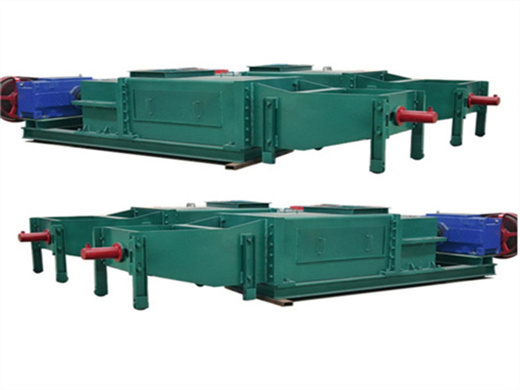

Peanut Processing Characteristics and Quality Evaluation

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5 KW

- Country: ghana

Wang Li and Wang Qiang (2012) classified the protein gelation and solubility of different peanut varieties and quality characteristics of peanut oil and export peanut by using K-means cluster

Process and characteristics of cold pressed peanut oil

- Type: peanut oil processing machine

- Production capacity: 10TPH to 100TPH

- Voltage: According to customer requirements

- Weight: Up to specification

- Dimension (L*W*H)): 1360*950*1170mm

- Power ( W): According to customer's requirements

The peanut oil produced has high precision and high smoke point, so there is less lampblack when cooking. Cold oil press machine. The natural fragrance of nut plants is very precious and complex. There are around 200 ingredients in the natural fragrance of peanut, therefore, any good essence could not blend real authentic aroma of peanut oil.

The approaches used to the extraction processes of peanut oil is directly affected its quality. Generally, peanut oil can be extracted from shelled and crushed peanuts using various methods such as conventional process includes mechanical pressing, solvent extraction and modern pretreatment methods like dry air heating, ultrasonicating

industrial peanut oil extraction plant with in ghana

- Usage: peanut oil

- Production capacity: 15-250 KG/h

- Voltage: 220v

- Main components: Motor

- Weight: 90 KG

- Dimension (L*W*H): 650*570*1125MM

FFb oil yield: 22% CPO; FFB oil yield: 2% CPKO: Exporting Countries: ghana; Depending on the variety and other cultivation details, peanuts contain between 45 to 55% oil, with the Spanish variety typically boasting the highest oil content. While many peanut oil mills rely on the traditional double press method, some plants are turning to high

Graphical Abstract Graphical Abstract The quality and safety of edible plant oil is very important. In the entire production and industrial chain, including cultivation, harvesting, processing, and storage, it is necessary to layers of checks and set evaluation indicators to ensure the quality and safety of edible plant oils, which were challenged by the deteriorating environment.

Peanut oil pressing process - Edible Oil Expeller Machinery

- Type: cooking oil extraction machine

- Voltage: 220V/380V

- Dimension (L*W*H):Standard

- Power (W):Standard

- Weight :Standard

- Certification:CE ISO

Second,in the high-temperature pressing process, 10-18% peanut shells must be added so that the friction coefficient of the oil press chamber can meet the conditions of peanut kernel oil extraction. The peanut shell is composed of crude fiber. The addition of peanut shell not only absorbs oil, but also makes the rate of peanut cake separation

Peanut oil (groundnut oil), as a kind of light yellow transparent edible oil with a pleasant fragrance and good taste, is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid).

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Raw Material: peanut

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 1055*805*345mm

- Voltage: 220V/50HZ three-phase

- Weight: 27.1 KG

- Main components: Motor, motor

a plant-based alternative to meat that would be attractive to health-conscious consumers. for extracting high-quality peanut oil. Processes 2023, 11, 2512 10 of 56. 2.2. Cold Pressing.

Application: crude Peanut oil processing plant; Function: Chemical oil refining and physical oil refining; Application range: 10-1000tpd; Advantage: Low consumption; Power consumption: 17.5kwh-24kwh; Steam consumption: 200-300kg per one ton crude oil; Exporting Countries: ghana; Salad and cooking oils or frying fats can be made almost solely