Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Type: peanut oil mill

- Usage/Application: peanut, groundnut

- Production capacity: 100~400 kg/h

- Voltage: 220 V/380 V

- Weight: 1300KG

- Dimension (L*W*H): 2200*1600*2150mm

- Power (W): 20 KW

- Country: nairobi

Then the cleaned peanut seeds are sent to the oil milling plant to be pressed into oil by oil presses. However, the crude peanut oil usually contains a number of impurities. So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further

Peanut Oil Making Machines for Sale|Best Manufacturer

- Type: peanut oil processing machine

- Production capacity: 5~6 tons/day

- Voltage: 380V/440V

- Warranty: One year warranty against manufacturer defects.

- Weight: KG

- Dimension (L*W*H): Depends

The oil content of peanut is approximately 42% to 52% oil. Peanut oil is mainly used for cooking purpose as it contains lots of protein and 80% unsaturated fatty acids like oleic acids and linoleic acids. Peanut oil is in light yellow transparent color and has a fragrant smell, and their taste is very delicious. Groundnut / Peanut Oil Making

We are able to supply the professional oil refining plant and related oil refining equipment. With a high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in a large oil plant. SEE MORE

Buy Ideal Peanut Oil Making Machine at Wholesale Price

- Usage: peanut oil

- Production capacity: 5-100T/H

- Voltage: 220V/380V/440V

- Weight: Depends on capacity

- Dimension (L*W*H): Depends on capacity

- Power ( W): 100kw

Edible oil refining is of great importance for the specialized peanut oil mill plant for business purpose since it can greatly improve the quality, including the color, taste, shelf time and more. The main process of peanut oil refining is degumming, deacidification, decolorizing and deodorizing.

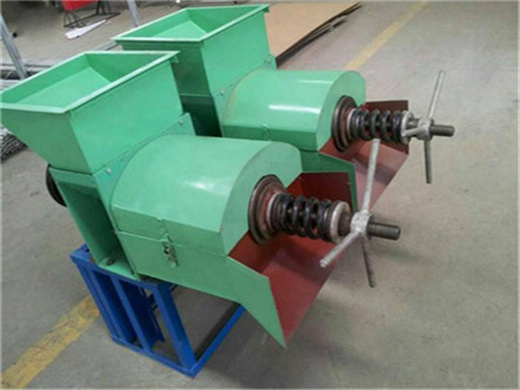

So the quality of oil can be guaranteed. Easy Operation and Less Maintenance; Small oil mill adopts screw oil expeller to extract oil, so it has all the merits of screw peanut oil press. So, it is very easy to operate and maintain. Reliable Peanut Oil Mill Supplier. 5TPD Peanut Oil Processing Plant Exported to Sudan. Above is a customized small

BEST Price Peanut Oil Extraction Machine for High Efficient

- Type: cooking oil extraction machine

- Production capacity: 250-300 KG/H

- Power (W ): 3KW

- Voltage: 380V

- Dimension (L*W*H): 2000x1200x2500mm

- Weight: 2200kg

YZS series peanut oil extraction machine is passed with ISO9001:2015 and CE certifications. Apart from peanut, they are also suitable to extract oil out from a very wide range of raw materials, including palm kernel, cotton seeds, soybean, moringa seeds, tea seeds, south africa seeds, rapeseed, mustard seeds and more.

These oil mill can process a number of oilseeds like peanut, soya, cotton seeds sunflower seeds, corn germ, rape seeds, canola, castor, sesame, neem seed, sheanut, palm kernel and the like. The most important equipment in the entire milling / pressing process is oil expellers which are used for high oil content seeds and also used for smaller

Peanut Oil Production Line,Peanut Oil Pressing Plant - Oil mill

- Raw Material: peanut

- Production capacity: 10-500TPD

- Dimension (L*W*H): 2.3x2.8x3<br /Weight : 12000 KG

- Voltage: 380/440

- Warranty: 3 years, long-term technical support

- Main components warranty: More than 5 years

Each stage, from cleaning and dehulling to oil extraction and refining, is critical to ensure high-quality, pure peanut oil that meets commercial standards. Small-scale setups rely on mechanical pressing for simplicity, while large-scale production lines utilize solvent extraction and advanced refining techniques to maximize output and meet

This EXTRacted oil has many impurities and has to be cleaned and this is the step which takes a long time. The crude oil is sent to the oil refinery plant where the oil is sent for the further processing. It’s done on a large scale in oil refinery but the user can actually employ an oil filter to press and filtrate the oil.