Small Coconut Oil Extraction Production Machine Starts

- Type: coconut oil machine

- Usage/Application: coconut, copra

- Press series: Fifth

- Voltage: 220 V

- Transportation package: Standard export packaging

- Capacity: 8-15kg/H

- Oil yield: 30-60%

- Country: lagos

Mechanical Coconut Oil Extraction Process: the dry coconut with 10% ~ 12% moisture is transported to the automatic scale to remove the broken iron through the magnetic chamber, and is ground into particles of about 0.3 cm in diameter, and the particles are pressed into a thin sheet to enlarge the surface of the dried coconut oil extracting.

Coconut oil process Brochure - Crown Machinery

- Type: coconut oil processing machine

- Material: stainless steel

- Main parts: Filter, Freezer and Filter

- Power: Electricity

- Price: Negotiation

- Color: According to customers

Refined coconut oil is the processed coconut oil that does not contain any impurities. It is more precisely called RBD coconut oil. RBD stands for refined, bleached, and deodorized. Therefore, refined coconut oil has a neutral scent and flavor. The smoke point of refined coconut oil is higher than that of unrefined coconut oil.

Coconut oil or copra oil, is an edible oil extracted from the kernel or meat of mature coconuts harvested from the coconut palm (Cocos nucifera). It has various applications. Because of its high saturated fat content, it is slow to oxidize and, thus, resistant to rancidification, lasting up to six months at 24 °C (75 °F) without spoiling.

Coconut Oil Production line

- Usage: coconut oil

- Production capacity: 20-2000T/day

- Voltage:as crude oil refinery capacity

- Weight: as crude oil refinery capacity

- Dimension (L*W*H): as crude oil refinery capacity

- Power (W): as crude oil refinery capacity

Flow chart of coconut oil production line: copra →cleaning→ drying →crushing→softening→ pre pressing → twice pressing →filteration → crude oil tanks → refined section → refined coconut oil Pre-treatment and pre-press Pretreatment and prepressing section is a very important section before extraction. It will directly affect extraction effect and oil quality. (1) Cleaning

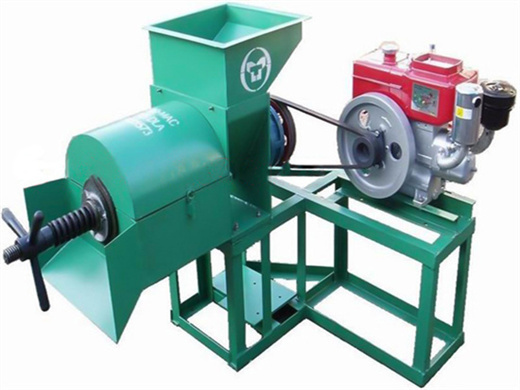

Copra oil expeller is a continuous oil press machine for once pressing of copra or the second pressing of pre-pressed copra cake in the coconut oil production line to obtain coconut oil. The operations from copra feeding, copra cooking, oil pressing and cake discharging are achieved automatically and continuously.

Coconut Oil Press / Oil Extraction Machine Manufacturers

- Type: cooking oil extraction machine

- Production capacity: 1t/day-1t/hour-100%

- Dimension (L *W*H): 1055 *805*345mm

- Voltage: 220V/50HZ three-phase

- Weight: 27.1 KG

- Main components: Motor, Motor

The cultivation of coconut is spread over the entire coastal belt and also some interior tracts. Compared to all other oil seed crops coconut has the highest productivity as well as consistency in production. Below are the Technical Details about our Coconut Oil Press machine:

Hence it is also called cold pressed coconut oil. (Read more: Virgin Coconut Oil (VCO) Extraction Plant Process) Expelled Coconut Oil – Made from Copra. Extracted from dried coconut meat – Copra. The coconut is dried in the sun or in a drier before pressing the oil. The copra is then sent to a coconut extracting machine to obtain crude oil.

6YL-series Coconut oil production line - Mikim Machinery

- Raw Material: coconut

- Production capacity: high

- Power (W): 18.5 KW

- Voltage: 220V, 380V or other

- Dimension (L*W*H): 900*850*1550mm

- Weight: 1000kg

Order Quantity: 3T Automatic Coconut Oil Production Line. Model: 3T Automatic Coconut Oil Production Line. Customer Basic Information:Our customer is a coconut grower in Sri Lanka. His goal is to invest a coconut production line which designed to handle a large volume of coconuts efficiently, ensuring optimal oil extraction while preserving the

A thousand mature coconuts weighing approximately 1,440 kilograms (3,170 lb)yield around 170 kilograms (370 lb) of copra from which around 70 litres (15 imp gal) of coconut oil can be extracted. Pretreatment and prepressing section is a very important section before extraction.It will directly affect extraction effect and oil quality. Flow