Small Size Peanut Oil Manufacturing Machine in Cameroon

- Type: peanut oil refinery machine

- Usage/Application: peanut, groundnut

- Production capacity: 200~2000T/D

- Voltage: up to specification

- Function: machinery for palm oil production

- Dimension (L*W*H): 2050*1350*2000Weight: 1000kg

- Power ( W): 7.5 kW

- Country: cameroon

Setting up a small size peanut oil manufacturing line in Cameroon is relatively easy and the investment cost is also relatively low due to the rich peanuts and sufficient labors. Below is the peanut oil manufacturing machine that brought buy one of our customer who is going to setup a Small Size Oil Production Line in Cameroon to produce high

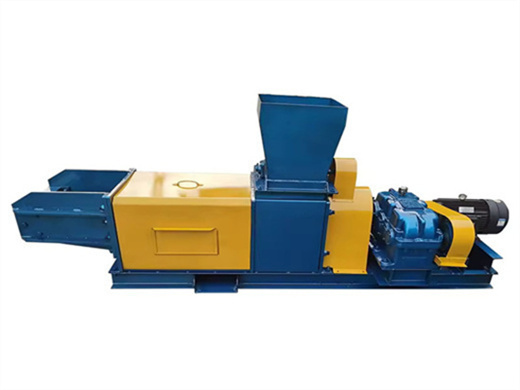

Batch type peanut oil refinery plant and continuous peanut

- Type: peanut oil refinery machine

- Production capacity: 100% crude sunflower oil price

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W*H): Depends on its capacity

- Power (W): 10-50kw

1-10tpd small scale batch type peanut oil refining machine. 1-10tpd small scale peanut oil refining machine is a widely used edible oil refining machine which is suitable for various vegetable and animal oils, such as soybean oil, peanuts oil, sunflower oil, rape seeds oil, cottonseeds oil, coconut oil, rice bran oil, palm oil, palm kernel oil

Hot Pressing is the traditional process of peanut oil: peanut oil is steamed fried and pressed, usually at a temperature above 120 ℃ with a high rate of oil output. But because of the high production temperature, the peanut protein is usually severely denatured and the lose great mount of nutrients.

Buy Ideal Peanut Oil Making Machine at Wholesale Price

- Usage: peanut oil

- Production capacity: 75-150Kg/h

- Voltage: 220V/380V

- Main components: PLC

- Weight: 2000 KG

- Dimension (L*W*H): 900*1100 *1650 mm

This is a small scale edible oil production line that connects the basic peanut oil making machines. It is mainly equipped with conveyor, sheller, cooker, oil press and oil filter machine. For many starters who are planning to involve in peanut oil making business, this is a BEST choice due to its low cost, high oil output and easy operation.

Batch-type edible oil refining equipment offers a practical solution for small-scale edible oil production, combining flexibility, efficiency, and high-quality output. Its modular design, ease of operation, and cost-effectiveness make it an excellent choice for the small-scale oil mill plant, ideal for producing high-quality refined edible oil

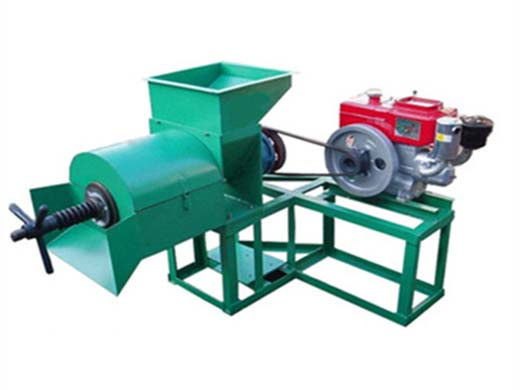

Small Scale Cold Oil Press Machine - Peanut Oil Press Machine

- Type: cooking oil refining machine

- Voltage: 220v/110v

- Weight: 11 KG

- Dimension (L*W*H): 43x27x35cm

- Main components: Motor

- Oil capacity: 3.5-5.50kg/h

Small Scale Cold Oil Press Machine Section Introduction: This oil press suitable for cold and hot pressing, adopts the principle of multi-stage gradual compression to increase the pressure in the barrel quickly and thus maximizing the oil output Oil output rate is greatly improved for its unique design

Small scale oil refining plant Introduction: Hongde machinery sets of small scale cooking oil unit equipment won the national patent (patent number: ZL 99 252888.7), is currently developing the third generation of our edible oil making machine.Our small scale oil refinery plant are great choice for small capacity oil refinery machine.The small scale oil refinery production plant can remove

Peanut Oil Making Machines for Sale|Best Manufacturer

- Raw Material: peanut

- Production capacity: 50-3000TPD

- Power (W): Depends on palm oil production

- Voltage: 220V/380V/440V

- Dimension (L*W*H): Depends on production

- Weight: Depends on production

Our Machinery is an experienced and reliable peanut oil machine manufacturer and supplier, offering high quality single oil press, automatic oil press, small oil production line and oil refining machine set at factory price. Besides, we can offer turnkey project plan for establishing complete oil extraction plant.

This EXTRacted oil has many impurities and has to be cleaned and this is the step which takes a long time. The crude oil is sent to the oil refinery plant where the oil is sent for the further processing. It’s done on a large scale in oil refinery but the user can actually employ an oil filter to press and filtrate the oil.