How To Establish Small Scale Oil Mill of Cotton Seed? Mini

- Type: cottonseed oil refining plant

- Usage/Application: cottonseed

- Voltage: 380v

- Weight: 650 KG

- Raw material: Oilseeds

- Oil type: Cooking oil

- Main components: Motor, Gear

- Country: botswana

Read more about cottonseed oil solvent extraction method >>. Set Up A Cottonseed Oil Mill Plant. This small small oil mill is not only suitable for cotton seeds, it is also ideal choice for extracting oil from many other oil seeds and nuts, such as mustard seed, peanut, flaxseed, linseed, poppyseed, groundnuts, sesame seed, canola seed, sunflower seed, soybeans, etc.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil refinery machine

- Production capacity: 35-550kg/h cold press machine

- Voltage: 380V or local voltage

- brDimension (L*W*H): 900*850*1550mm

- Dimension (L*W*H): 900*850*1550mm

- Power (W): according to the capacity of the cold press machine

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

If you are planning to set up a cottonseed oil refining plant or oil refinery equipment for other oilseeds, you are in the right place!. We take the opportunity to intoduce Our Machinery, an ISO 9001 Company, a leading oil mill engineering firm, established in 1997, specialist in vegetable oil extraction and refinery field.

Cottonseed Oil Processing Machines Set up Complete Oil Mill Plant

- Usage: cottonseed oil

- Production capacity: 5TPD-100TPD

- Voltage: 380V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, sunflower/seed oil extraction

- Weight: 550 KG

- Dimension (L*W*H) : 1700mm*800mm*1200mm

Cottonseed oil refining machine mainly has three types, bathc type, semi-countiuous type and continuous type. After refining, cottonseed oil meeting national standards can be obtained and sold on the market to obtain profit income. So far, the technological process of cottonseed oil production by solvent has also ended. (Related Project

The refined cottonseed oil has removed gossypol and other toxic substances and can be eaten by humans. The absorption rate of cottonseed oil by the human body is 98%. 3. Cottonseed oil refining process. Cottonseed oil crude oil→degumming→deacidification→washing→decolorization→deodorization→winterization→finished first-grade

Small Edible Oil Processing Plant Setup Costs & Tips

- Type: cooking oil refining machine

- Production capacity: other

- Dimension (L*W*H): 2600X1700X1950mm

- Voltage: optional

- Weight: 1350 KG

- Main components: MACHINE

If you choose us, we will offer the most favorable price to help you set up the small scale edible oil mill plant. (Related post: Cottonseed Oil Manufacturing Plant Project Report >>) Small Scale Edible Oil Processing Machines. Small edible oil processing plant connects small types of oil processing machines together to realize the continuous

The following video is about a small scale edible oil plant set up in India, which includes both oil pressing machine and oil refining machine. This factory is built for processing mustard seeds. View the video below to see how the small edible oil refining unit works. (Related Post: Cost Setting up Edible Oil Plant in India >>)

Cotton Seed Oil Manufacturing Project Report - Idea2MakeMoney

- Raw Material: cottonseed oil

- Production capacity: 1TPH-100TPH

- Power (W): 11 KW

- Voltage: 220V/380V

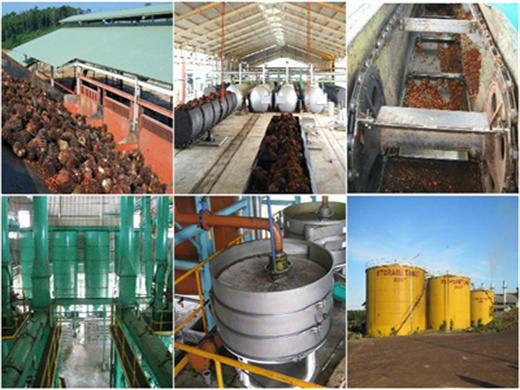

- Dimension (L*W*H): as per Malaysia palm oil factory specifications

- Weight : 1000kg

The selection of the filter is one based on impurity content in crude oil and oil refining capability. Cotton Seed Oil Manufacturing Project Report/ Economics of Cotton Seed Oil Manufacturing in India. Cotton Seed Oil Project Report – Land and building: Rs. 5,000

This practice permits mills to produce and mar- ket a consistently light-colored, prime bleachable summer yel- low cottonseed oil at reduced cost and refining loss. As a result, the yield of refined cottonseed oil, obtained from low-grade cotton seeds, increased by 1.1 times (90%) (compared to the traditional one (85.1)).