Agri-Pure Lauric Oils - Europe, Middle East, Africa | Cargill

- Type: coconut oil machine

- Usage/Application: coconut, copra

- Package: Glass bottle

- Raw material: Sesame seed

- Shelf life: 2 years/24 months

- OEM: Yes

- Non-GMO: Yes

- Country: johannesburg

Agri-pure® AP-620 is fully refined hydrogenated coconut oil. Hydrogenation enhances the stability and colour of the oil, and increases its melting point to ~32°C. Agri-pure® AP-15 is fully refined palm kernel oil containing approximately 47% of lauric acid and 6% of mid-chain (C8 and C10) fatty acids.

Confectionery Fats Application Guide - Cargill

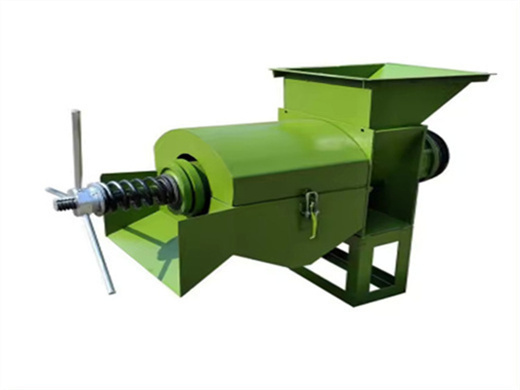

- Type: coconut oil processing machine

- Voltage: 220V, 380V or other

- Power (W): depends on capacity

- Capacity: 1tpd-200tpd

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity capacity

Cargill® HB-102 Hydrogenated Palm Kernel Oil 102 Cargill® HB-106 Hydrogenated Palm Kernel Oil 106 Cargill® HB-112 Hydrogenated Palm Kernel Oil 114 Cargill® Coconut 76 Coconut Oil 79 Cargill® HB-100 Hydrogenated Coconut Oil, Hydrogenated Palm Kernel Oil 101 Cargill® Coconut 92 Hydrogenated Coconut Oil 97 Cargill® Coconut 110 Hydrogenated

Here are the sub-types of refined coconut oil: Hydrogenated Coconut Oil – This type of refined coconut oil isn’t edible. Better stay away from it if you’re planning to take coconut oil orally. It goes through a hydrogenation process wherein unsaturated fatty acids turn into saturated fats or trans-fat. It may cause heart disease or stroke.

Hydrogenated Coconut Oil: Derivative RBD Coconut Oil Product

- Usage: coconut oil

- Production capacity: 96%

- Voltage: 380v (or customize)

- Main components: Motor

- Weight: 1.5 KG

- Dimension (L*W*H): 1750*2740*1100mm

Yes, hydrogenated coconut oil can be used for frying. Its high smoke point and stability make it suitable for high-temperature cooking methods, including frying. It remains stable and does not break down into harmful compounds when exposed to high heat. What are the uses of hydrogenated coconut oil in cosmetics? In cosmetics, hydrogenated

It is an oil rich in saturated fatty acids, about 90%. Over 50% of its fatty acids are short chain (less than or equal to 12 carbons, lauric) and so along with palm oil and palm kernel it is known as an oil of the lauric oils family. It is the oil with a higher content of caprylic fatty acid, up to 10%.

coconut oil process bottleneck in johannesburg

- Type: cooking oil extraction machine

- Production capacity: 100% oil press machine

- Power (W): 5.5 ~ 18.5 KW

- Voltage: 220V/380V/440V

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Weight: 950KG

coconut oil process bottleneck in johannesburg,Coconut - Wikipedia,The process of husk extraction from the coir bypasses the retting process, using a custom-built coconut husk extractor designed by ASEAN–Canada Forest Tree Seed Centre in 1986.

Palm Kernel oil is extracted using petroleum products that leave a residue. Palm oil (from the fruit) is easily extracted, so no harmful chemicals are used. Tropical oils get a bad rap. There’s a lot of good things in all natural foods - including, for example, coconut oil.

What is hydrogenated coconut oil? Composition and Uses

- Raw Material: coconut

- After-sales Service: Online and Video

- Press Series: Fifth

- Structure: Vertical

- Voltage: 380V

- Weight: 950kg

As such, hydrogenated coconut oil is generally considered less healthy than regular, unprocessed coconut oil. 4. What are the uses of hydrogenated coconut oil? Hydrogenated coconut oil is used in various food products, especially in the baking and confectionery industry, where solid fats are needed for texture and consistency. It is also used

A higher melting point is desirable in these warm climates, so the oil is hydrogenated. The melting point of hydrogenated coconut oil is 36–40 °C (97–104 °F). In the process of hydrogenation, unsaturated fats (monounsaturated and polyunsaturated fatty acids) are combined with hydrogen in a catalytic process to make them more saturated