Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil processing machine

- Usage/Application: cottonseed

- Production capacity: 100 tons/day

- Voltage: NONE

- Warranty: Not available

- Weight: 100 KG

- Dimension (L*W*H): 100*100*100

- Country: zimbabwe

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

Cottonseed Oil Processing Plant | Extraction Flow

- Type: cottonseed oil processing machine

- Production capacity: 50-200 tpd oil expeller

- Voltage: 220V/380V/ 440 V

- Weight: 850 KG

- Dimension (L*W*H): 5432*2636*2345

- Power (W): depends on capacity

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption.

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

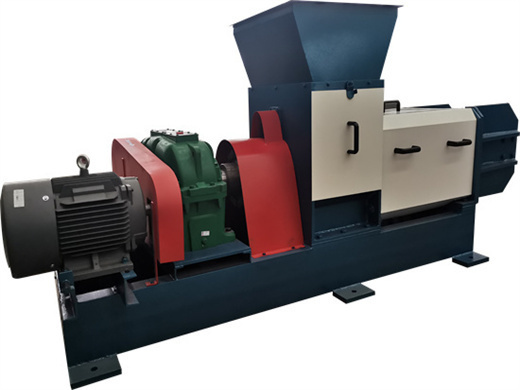

Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Production capacity: 120-1200 kg/h

- Voltage: 380 V

- Main components: Motor, gearbox, squeezing system

- Weight: 1500 KG

- Dimension (L*W*H): 2*1.6*2.7

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

How To Establish Small Scale Oil Mill of Cotton Seed? Mini

- Type: cooking oil extraction machine

- Production capacity: 50-1200t per day

- Power (W): 37-220kw

- Voltage: 110v,220v,380v,440v

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

Cottonseed Oil offers a unique business opportunity. By 2028, the global cottonseed market will reach a value of over 5 billion dollars. It is foretasted to grow by 3.2% over the next few years. This increased demand for cottonseed oil is mainly due to the food processing and snack food industry.

Then, the crude cottonseed oil is made and the cottonseed oil cake is discharged for next processing for feed or other usages. Oil Refining: Since the crude cottonseed oil contains high content of gossypol, it needed to be refined to improve the quality and ensure the final refined cottonseed oil is completely safe for eating.

Think of Setting up a Cottonseed Oil Processing Plant?

- Raw Material: cottonseed oil

- Production capacity: 1-500T/D

- Power (W): according to capacity

- Voltage:380V

- Dimension (L*W*H)): various with capacity

- Weight: changed with capacity

Cottonseed Oil Processing Flowchart Cotton seed—>delinting—> decorticating—>prepressing—>solvent extraction—>refining crude oil —>refining. Cottonseed oil is a vegetable oil extracted from the seeds of the cotton plant after the cotton lint has been removed.

Cottonseed oil extraction involves a series of oil manufacturing process and professional oil processing machinery. Whatever your cottonseed oil mill plant is small or large, the basic manufacturing process is needed to produce high quality cottonseed oil. The detailed cottonseed oil manufacturing processes is as follows. Cleaning: Getting rid of organic impurity (stems and leaves, […]