Kumar’s Palm Kernel (PK) Series Oil Expeller Machine

- Type: palm kernel oil expeller

- Usage/Application: palm fruit, palm kernel

- Voltage: 380V

- Appearance: Vertical

- Customized: Customized

- Press Series: Fourth

- Press Materials: Sunflower, Soybeans, Coconut, Peanuts, Mustard

- Country: lagos

Specially designed and manufactured for maximum oil extraction from palm kernel. Minimal residual oil content in the second press cake. Independent gearbox system reduces noise level, consume less power and ensure zero contamination of mineral oil with edible oil. Alloy steel with ultrasonically tested screw shaft with heavy-duty branded bearings.

Palm Kernel Oil Expeller

- Type: palm oil processing machine

- Voltage: 220 V/110 V

- Dimension (L*W*H): 450*180*300 mm

- Oil type: Cooking oil

- Main components: PLC

- Weight: 1400 kg

Oil Residue in Palm Kernel Cake: 7 to 8% Maximum: Motor Rating: 15 HP/ 410V / 3-Phase / 50 Hz: Includes: Seed Cooking Kettle, Foundation Base Frame, Pulley etc. Includes: Seed Cooking Kettle, Foundation Base Frame, Pulley etc. Function: To Crush the Palm Kernel Seeds to get Palm Kernel Oil and Palm Kernel Cake

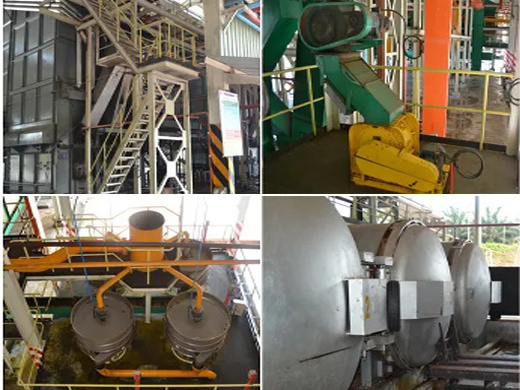

Shells are sent to the boiler system as fuel, and palm kernels are pressed by palm kernel oil mill machine. Palm kernel oil filteration: the vibrating filter is used to filter the oil in order to remove the impurities in palm kernel oil. Cleaning: magnetic separator is used to remove metal debris and vibrating screen is used to remove stones

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

- Usage: palm oil

- Production capacity: 100% raw cooking oil price

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W) *H): Depends on its capacity

- Power (W): Depends on its capacity

The palm kernel oil expeller machine is also added with the seed frying and automatic heating function which changes the traditional heating method of cake grinding press, so as to shorten the preparatory work time, reduce the energy consumption & the abrasion of the machine and prolong the service time of expeller.

Palm kernel oil press machine, also known as palm kernel oil expeller. This machine is suitable for peanut, palm kernel, sesame, palm, soybean, sunflower, rapeseed, olive etc. It is high efficiency with mature product structure and process, the oil yield can be comparable to the large oil press.

Palm kernel oil press, small palm oil extraction machine

- Type: cooking oil extraction machine

- Production capacity: palm kernel oil press equipment

- Power (W): depends on capacity

- Voltage: 220V, 380V or other, according to your country

- Dimension (L*W*H): depends on capacity

- Weight: depends on capacity

In conclusion, the palm kernel oil press is an advanced machine that provides a reliable and practical solution for extracting palm kernel oil. It offers significant benefits over traditional oil press machines, making it a popular choice among farmers and oil extrusion workshops. With proper pre-treatment and careful handling, this machine can

The cleaned Kernels are fed to a palm kernel oil expeller machine, which consists of a main shaft and worms, which rotates within a stationary perforated cylinder called a cage or barrel. As the main shaft turns, there is a decrease in volume resulting in pressure in the cage.

High Efficiency Palm Kernel Oil Expeller - Wholesale Available

- Raw Material: palm

- Voltage: 230-380-430

- Dimension (L*W*H): 20m*16m*15m

- Power (W): 40kw/h

- Weight: 30 tons

- Squeeze impurities in crude oil: 0.01%

Technical Specifications of Palm Kernel Oil Expeller. The palm kernel oil expeller typically has a power capability ranging above 35-40 hp, allowing it to effectively extract oil from palm kernels. With a maximum range of 3-4 tons, this machine is designed to handle large quantities of palm kernels efficiently.

Palm Kernel Oil Solvent Extraction Plant is recommended for large Palm Kernel Oil Mill with high capacity. However, For the purposes of small-scale operations it is sufficient to mention the solvent extraction process is an alternative for high capacity mills. However the process is not recommended for small enterprises. Basic Unit Operations