Expert Tips For Coconut Oil Refining Process To Profitable Plant

- Type: coconut oil refinery plant

- Usage/Application: coconut, copra

- Production capacity: 96%

- Voltage: 220v/110v

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

- Weight: 36 kg

- Dimension (length x width x height): 67*24*42 cm

- Country: lagos

Coconut Oil Physical Refinery Process - Reducing Loss and Enhancing Quality. Coconut oil has very little gum content and does not require strict acid refining for degumming; while coconut oil is very easy to saponify, if chemical alkaline refining is used, improper process parameters will increase the additional loss of neutral oil.

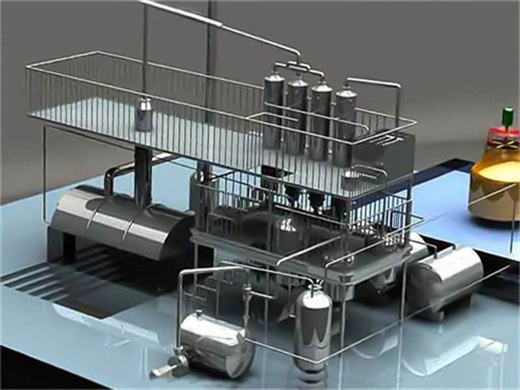

Coconut Oil Refinery Plant

- Type: coconut oil refinery machine

- Production capacity: 15T~100TPD

- Voltage: 220V/380V

- Weight: related to capacity

- Dimension (L*W*H): 120*80*12m

- Power (W) : according to capacity

Coconut Oil is light yellow color oil obtained by mechanical screw pressing of dried coconuts. Coconut Oil Refining Plant has the input as raw coconut oil and gives output as RBD coconut oil. We are leading manufacturers and suppliers of Coconut Oil Refining Plants to process the crude coconut oil into refined coconut oil.

IMARC Group’s report, titled “Coconut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a coconut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as

Refined Coconut Oil and Detailed Refing Process - Oil Mill Plant

- Usage: coconut oil

- Production capacity: 30-500T/D

- Voltage: 380V-415V

- Weight: depends on the cooking oil machine cooking oil machine mode

- Dimension (L*W*H): depends on the cooking oil machine mode

- Power ( W): depends on the cooking oil machine mode

The refined organic coconut oil is processed using the organically approved methods of physical extraction and refining. For the extraction step, the coconuts are broken into pieces and the coconut meat is allowed to dry, and once it is dried, the meat or flesh of the Coconut is hydraulically pressed at 100 - 130 degrees to extract the oil.

Fatty acid composition. The changes to the fatty acid composition during the coconut oil refinement process are shown in Table 2.The fatty acid profiles of the crude, degummed, neutralized, bleached, and deodorized oils were not significantly different from those reported in the literature; lauric acid (C12:0), myristic acid (C14:0), oleic acid (C18:1), and palmitic acid (C16:0) were present

Design Data Book To Process Coconuts Into Refined Virgin

- Type: cooking oil refining machine

- Automatic grade: Semi-automatic

- Production capacity: 30-70 kg/h

- Dimension (L*W*H): 900*850*1550mm

- Power (W): 7.5 KW

- Voltage: 220 V/380 V

This document provides design details for a coconut oil refining plant. The plant will process 10 tons of coconuts per day to produce refined virgin coconut oil. The process involves dehusking, grinding, drying, pressing, centrifuging, filtering, and refining coconut material to extract and purify the oil. The plant requires equipment for each processing step and utilities like electricity

As a trader of major commodities globally, our key activities in the coconut oil supply chain include: Buying copra (dried coconut meat) from farms, smallholder farmers and cooperatives, consolidators and traders; Processing copra at our crush plants and coconut oil at our refineries; Sourcing, trading and refining coconut oil from third-party

Master Coconut Oil Processing: From Pretreatment to Refining

- Raw Material: coconut

- Production capacity:≥95%

- Dimension (L*W*H):1685*1230*1380

- Voltage:380V

- Weight: 600 KG

- Main components: gearbox, others

Coconut oil processing plant. Explore the world of coconut oil production with Huatai's advanced facilities, designed for high efficiency and maximum yield. Our video highlights our capacity to process vast quantities of coconut oil, from 30 to 1000 TPD, and our sophisticated solvent extraction techniques that ensure every drop of oil is captured.

The coconut oil production line mainly includes copra pretreatment and oil pressing process, oil refining process. Copra cake produced after pressing can be used as animal feed. We provide 30-1000 TPD coconut oil processing machine and 1-600 TPD coconut oil refinery machines.