Design, Development and Performance Evaluation of an Improved

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Product type: Nut and seed oil

- Processing type: Refined

- Purity (%): 100

- Packaging: Bottle glass, bulk, can (canning), drum, jar, plastic bottle, vacuum packaging

- Cultivation type: Organic

- Country: lusaka

flesh. Both palm oil and palm kernel oil serve as vital raw materials in the production of diverse products such as margarine, candles, epoxy resins, soaps, detergents, lubricants, pomades, cosmetics, and more. Additionally, the palm kernel cake, a byproduct obtained during the extraction of palm kernel oil, is employed as an additive in the

Palm Kernel Oil Plant - Oil Expeller. Edible Oil Production Line

- Type: palm oil processing machine

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 0.5-10T

- Dimension (L*W*H): 1.5*2.6*3.6M

- Power (W): 11KW

Palm Kernel Oil Pressing Step. The pretreated palm kernel material is then transferred to the screw oil press for extraction. Equipped with the automatic temperature-controlling device and crude oil filter tank, Our integrated screw oil press operates easily and has high oil output.

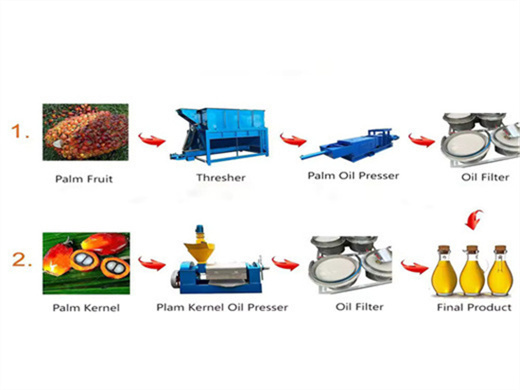

Our Palm Kernel Crushing Plant is a facility designed to extract oil from palm kernels, which are the seeds found inside the fruit of oil palm trees. These kernels contain a significant amount of oil, separate from the palm oil extracted from the flesh of the fruit. Here's a brief overview of the process in a Palm Kernel Crushing Plant: 1.

Palm Kernel Oil Plant - Oil mill

- Usage: palm oil

- Production capacity: 10-3000 tons

- Voltage: 380v 440v

- Weight: Depends on the capacity of the equipment of corn oil

- Dimension (L*W*H): As capacity of corn oil equipment

- Power (W): As production of corn oil equipment every day

We offer complete palm kernel oil production lines and palm fruit oil production lines to meet your large volumes of palm oil production needs. Our patented palm oil processing technology transforms palm kernels into high-quality stable palm kernel oil through an efficient, meticulous, seamless, and sustainable process.

PALM KERNEL OIL PROCESSING PROCESS. Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit; Palm kernel Mechanical Pressing Unit; Palm Nut Cracking & Shell Separation Unit. Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

DESIGN AND FABRICATION OF A PORTABLE PALM KERNEL EXTRACTOR

- Type: cooking oil extraction machine

- Production capacity: 3-300T/DAY

- Dimension (L*W*H): 1700 *1300*1750 mm

- Voltage: 220V/380V/440V

- Weight: 30 kg, depends on capacity and configuration

- Main components: motor, pressure vessel, pump, PLC, others, gears, bearings, motor, gearbox changes

Is to design and fabricate a portable palm kernel oil extraction plant that willproduce 100kg-200kg of palm kernel oil per day using palm kernel and to reducewaste and improve the efficiency and output of palm kernel. This can only be * achieved by mechanizing the palm kernel oil extraction processes over the manual process of

Palm fruit oil extraction is a difficult task to undertake. Screw press technology offers a solution to its extraction. However, most screw press available requires high power input for effective

Design and Construction of a Palm Kernel Oil Extraction.pdf

- Raw Material: palm

- Production capacity: 100TPD

- Dimension (L*W*H): 800*650*1100

- Voltage: 380V/220V or as required

- Weight: 530 KG

- Main components warranty: 5 years

In this research work, the design and construction of a palm kernel oil extraction machine was carried. The results obtained with the palm kernel oil extraction machine and traditional methods are shown in Table 1. From the graph, the mechanical method via the use of palm kernel extraction machine is more efficient than the traditional method.

The kernels are further processed in palm kernel oil extraction plant to produce palm kernel oil (PKO) and palm kernel cake (PKC). The rate of FFA increase is much faster in broken kernels. So try to keep the kernel breakage as low as possible during the nut crushing processes. Palm Oil Extraction Manufacturer & Supplier