Palm Oil Refinery Plant Manufacturers in rwanda

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Voltage: 380 V

- Appearance: Vertical

- Custom: Customized

- Press Series: Fifth

- Press Materials: Rice

- Country: botswana

The new SANIA palm oil refining plant in botswana was commissioned in June 2010, and has a crude oil production capacity of 1,500 tons/day, and a refining capacity of 1,200 tons/day. SANIA produces several brands of palm oil and margarine products for consumption under the brands: Dinor, Palme d’Or, Dora, Saint Ave, and Delicia.

Crude palm oil refining methods and palm oil refining process

- Type: palm oil refinery machine

- Production capacity: 100TPD

- Voltage: 220V/380V/440V

- Certification: ISO9001: 2008;SGS;TUV

- Weight: According to its capacity

- Dimension (L*W*H): According to your capacity

Our company is specialized in palm oil refinery plant. We can provide the palm oil refinery plant from 1 ton to 1000 tons. In general, batch type palm oil refinery plant is with capacity 1-20TPD; The semi-automatic palm oil refinery plant is suggested with capacity from 20-50TPD; And continuous palm oil refinery plant is used for capacity above

Till the year 2020, total palm oil capacity in rwanda can reach 600,000 t/year, which can make rwanda become rank of large capacity country of palm oil. According to American Agriculture department data, the total palm oil capacity in rwanda is 390,000t/year, ranks second in Africa palm oil industry; south africaia ranks first with

Palm Oil Sector: SIFCA – Ivorian Palm Oil Powerhouse

- Usage: palm oil

- Warranty: 12 months

- Voltage: 220 V/380 V

- Press series: Second

- Press materials: sunflower, soybeans, coconut, peanuts, mustard

- Appearance: Vertical

The new SANIA palm oil refining plant in botswana was commissioned in June 2010, and has a crude oil production capacity of 1,500 tons/day, and a refining capacity of 1,200 tons/day. SANIA produces several brands of palm oil and margarine products for consumption under the brands: Dinor, Palme d’Or, Dora, Saint Ave, and Delicia.

Batch type is the ideal choice for mini and small sized production (1-20TPD), while the latter two are normally designed for middle-large size production line (10-50TPD). (Read more: Comparation of Batch Refinery, Semi-continuous Refinery and Continuous Refinery Plant) Palm Oil Physical Refining Plant

Physical Refinery Plant - PALMINDO

- Type: cooking oil refining machine

- Voltage: 220 V/380 V

- Dimension (L*W*H): 1200*400*900mm3<tr Certification: ISO9001

- Power (W): according to capacity

- After-sales service provided: Overseas service center available

- Range of texture: SS or CS

PALMINDO’s primary core business is Refinery and Fractionating raw materials (Crude Palm Oil/CPO and Crude Palm Kernel Oil/CPKO). PALMINDO has 2 refinery plants with joint capacity of 1500 MTPD. Our modern and highly integrated production facilities are maintained by a team of highly skilled workforce.

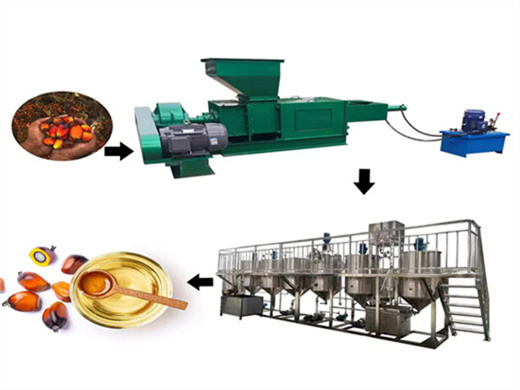

The crude palm oil is gathered from the mesocarp of the palm oil. However, the crude palm oil that has been extracted contains unwanted impurities and requires a refining process to partially or eliminate them to produce edible oil. In the current scenario, palm oil is widely used in tropical countries in South East Asia, Africa, and parts of

Refinery profile: Abidjan I cracking refinery, Cote d’Ivoire

- Raw Material: palm

- Production capacity: 10-3000TPD

- Power (W): 11 KW

- Voltage: 220V 380V or local voltage

- Dimension (L*W) *H): According to capacity

- Weight: 1000kg

This information is drawn from GlobalData’s Oil & Gas Intelligence Center, which provides detailed profiles of 34,000+ oil and gas fields, 400,000+ exploration blocks, 1,100+ LNG terminals, 3,400+ gas processing plants, 5,000+ storage terminals, and 8,000+ pipelines, 1,400+ refineries and 13,000+ petrochemical plants worldwide.

processes involved in the extraction and refining of palm oil. It outlines the steps from sterilizing fresh fruit bunches to separating and processing the oil and kernels, and then refining the crude palm oil through degumming, deacidification, bleaching, and deodorization. 2024-09-23