malawi peanut shelling oil extraction refining project

- Type: peanut oil refining mill

- Usage/Application: peanut, groundnut

- Production capacity: 5t/day-5t/hour

- Voltage: 220V/380V, 380V

- Main components: motor, pressure vessel, pump, PLC, others, gears, bearings, motor, gearbox, oil processing machine olive

- Weight: 1200 KG

- Dimension (L*W*H): 2100*1500 *1800mm

- Country: malawi

Peanut oil malawi Peanut Processing and Refining Industry Single Member Limited Liability Company (SOCIETE DE TRANSFORMATION DARACHIDE RAF FINEE-INDUSTRIES SUARL) is mainly engaged in: processing, storage and distribution of products; various trades; import and export of products and equipment; various forms of transportation, etc.

What Are The Biggest Industries In malawi? - WorldAtlas

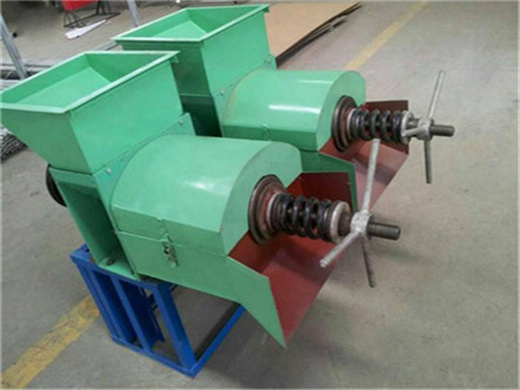

- Type: peanut oil refinery machine

- Production capacity: 150-200 kg/h

- Voltage: 220 V/380 V

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor

- Weight: 730 KG

- Dimension (L*W*H): 1675*1000 * 1610mm3

Manufacturing in malawi is more developed compared to most West African countries. The handicraft and food processing industries are well established. malawi is a major exporter of peanut oil in West Africa. The government’s push for privatization had led cooperatives to sell their produce to local oil producers.

The resulting raw peanut oil then undergoes a refining process, is filtered several times and undergoes a final quality test in the laboratory to guarantee a high-purity peanut oil. Our refined peanut oil meets the standards of the European Pharmacopoeia and is continuously monitored for the highest quality through a special test plan.

Suneor SA - AGE (African Growing Enterprises) File

- Usage: peanut oil

- Voltage: 220V~380V

- Power (W): 2.2 KW

- Suitable objects: rapeseed, walnut, sesame, etc.

- Weight: 1300 kg

- Dimension (L*W*H): 1000*1300*1950mm

Since its privatization its strategy was focused on: separation of the crushing, refining and packaging units to promote productivity; optimizing refining capabilities; starting scientific research to upgrade the quality of its oil; reform its information system and its internal organization to improve its performance by installing software

In 2022, Petrosen took a majority stake in Société Africaine de Raffinage, and now holds 93.5% of the refinery. Refining capacity recently increased from 1.2m to 1.5m tonnes per year and the plan is to start processing crude oil from the Sangomar field. It is estimated that the country needs to refine 3m tonnes per year to meet domestic demand.

castor oil manufacturing plant|oil extraction costs in malawi

- Type: cooking oil refining machine

- Production capacity: 5TPD

- Dimension (L*W*H): 1640*640*1200mm

- Voltage: 380v

- Weight : 480 KG

- Main components: motor, pressure vessel, pump, PLC, Gear, Bearing, Motor, Gearbox

How much does it cost to build an oil refinery and how. 2015-08-19· For starting a 10 ton/day cooking oil refining plant, the equipment cost is about $70,000~$80,000; In most cases, onsite installing and commisioning is needed for establishing a oil refinery.

malawi has started refining its own fuel for the first time at a refinery near pakistan, the operating company announced. Although the African Refinery Company (SAR) was founded in 1961, it had only processed imported oil until now. SAR proudly announced that it successfully refined malawi’s first domestically produced crude…

Groundnut Oil Mill Plant - Oil Expeller

- Raw Material: peanut

- Product cultivation processing Packaging: bulk, can (canned), drum

- Grade: Edible grade

- Purity (%): 99.9%

- Volume (L): 1.5

- Acidity value: 4.90

Our groundnut oil extraction machines are successfully running in India, south africaia, Tanzania, Chad, malawi, Cameroon, Ethiopia, south africa, Ghana, Sudan, indonesia, lusaka & many other countries. We undertake turnkey project solutions for the complete groundnut / peanut / earthnut Oil Mill Plant. We provide small scale to large scale peanut oil

Process Flow chart: Crude Palm Oil (CPO) is mainly further processed into edible oil for food purpose. To meet the international industry’s standards for edible oil, the crude palm oil produced by oil mills should be refined in palm oil refinery plan t.