Edible Oil Dewaxing Machine - Henan Hongde Cereals And Oils

- Type: cottonseed oil refinery machine

- Usage/Application: cottonseed

- Voltage: 380

- Power (W):Standard

- Certification:ISO9001

- Weight:Standard

- Dimension (L*W*H):Standard

- Country: johannesburg

The average cooling rate is 2℃/hour at the first 24 hours of the cooling period, the cooling rate of the next 24 hours is 0.5℃/hour and the last 24-hour' cooling rate is 1~2℃/hour. Then, the oil and precipitated wax crystals are separated by bag filtration in the filtration room at 15~18℃, and the filtration time is around 10~12 hours.

How to refine crude cottonseed oil into product oil?_Tech

- Type: cottonseed oil refinery machine

- purpose: cooking and others

- Description: high purity

- smell: original kitchen il smell

- color: bright fresh

- Material: stainless steel

The deodorization tower used in continuous cottonseed oil refinery plant. At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature. Similar with palm oil fractionation process, through cooling, crystallization and filtration

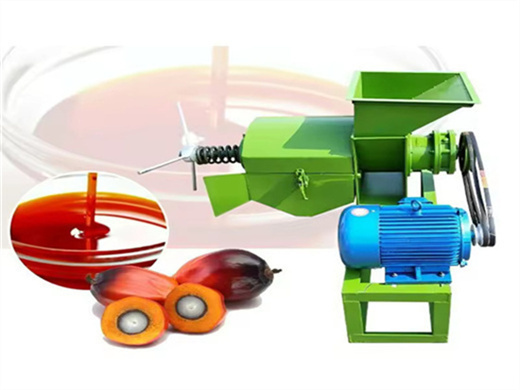

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

Manufacturing - website

- Usage: cottonseed oil

- Production capacity: 10-100TPH

- Voltage: 220V/380V/440V

- Weight: According to the cooking oil processing capacity

- Dimension (L*W) *H): 1200*400*900mm3

- Power (W) : 10-50kw

Headquartered in johannesburg, Marsavco has the largest, most technologically advanced food oil refinery in the DRC. Using equipment imported from De Smet of Belgium, the quality of oil is on a par with the finest in the world and undergoes strict quality controls throughout its computerised manufacturing process.

Human body consumption of cottonseed oil is up to 98%. Cottonseed Oil Needs Refining. It is said that refining process can reduce toxicity. Cottonseed oil is one of main cooking oil. But crude cottonseed oil contains gossypol (approximate 1%), colloid and waxiness (content varies with shell content), and the quality is poor. It isn’t good to

Cotton Seed Oil

- Type: cooking oil refining machine

- Production capacity: 1-500T/D

- Power (W) : depends on the oil machine mode

- Voltage: 380V-415V

- Dimension (L*W*H): depends on the oil machine mode

- Weight: depends on the oil machine mode

These products are extracted from the cotton seeds. The offered range of product is an unrefined lose oil and is supplied and demanded by Edible Oil Refinery Plants. These products are stored in high capacity storage tanks. Some of the features of these products are Rich in nutrients and hygienically processed.

$12.20-13.00. Shipping per piece: $1,986.78. Crude Cotton Seed Oil Refine Machine / Refinery Machine / Equipment 10-1000TPD up to Each Oil Refinery Machine

Cottonseed Oil Expeller Manufacturer, Seed Cleaning Machinery

- Raw Material: cottonseed oil

- Production capacity: 90-99%

- Dimension (L*W*H): 1400*600*600mm

- Voltage: 220v/380v

- Weight: 230 KG

- Main components: Motor

Established in 2004, Mitsun Engineering is an exporter and manufacturer of engineering machinery such as Oil Expellers, Cottonseed Oil Expeller, Cotton Seed Expeller, Seed Cleaning Machinery. Our company has the capability to supply various types of machines as per the drawings of the clients and their specific requirements.

The average cooling rate is 2℃/hour at the first 24 hours of cooling period, the cooling rate of next 24 hour is 0.5℃/hour and the last 24-hour’ cooling rate is 1~2℃/hour. Then, the oil and precipitated wax crystals are separated by bag filtration in the filtration room at 15~18℃, and the filtration time is around 10~12 hours.