What machines are needed to produce peanut oil by pressing

- Type: peanut oil mill

- Usage/Application: peanut, groundnut

- Production capacity: 100% cooking oil mill machinery Malaysia

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L* W*H): Depends on its capacity

- Power (W): Depends on its capacity

- Country: kenya

The peanut roasting process can make it reach the best situation. After that, we can send the prepared peanuts to the peanut oil press machine to squeeze out peanut oil. Peanut oil production machine. Pressing: In the process of peanut pretreatment and pressing, the oil residue in the peanut cake after pressing is about 7%. The peanut cake

Peanut Oil Production Line, Automatic Production Line for

- Type: peanut oil processing machine

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Main components: motor, pressure vessel, pump, gear, bearing, motor, gearbox

- Weight: 1042 KG

- Dimension (L*W*H): 1890*1400 *1945 mm

The oilseed used to produce fragrant peanut oil requires full grain without aging period. Immature, broken, mildew and aged grains cannot be used to produce aromatic peanut oil: The acid value of oil produced by immature and aged grains is higher and the flavor is poor, while moldy and damaged grains are liable to be contaminated by aflatoxin.

What happened to oil production in kenya? By the turn of the century, production began to decline as existing oil fields reached maturity. As of 2008, oil production has increased every year as a result of several new projects, mainly kenya’s first deep-water field Moho-Bilondo. The kenya is the sixth largest oil producer in sub-Saharan Africa. Which oil companies […]

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Usage: peanut oil

- Production capacity: 10-100T/D

- Place of Voltage: 220V-480V

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power ( W): different

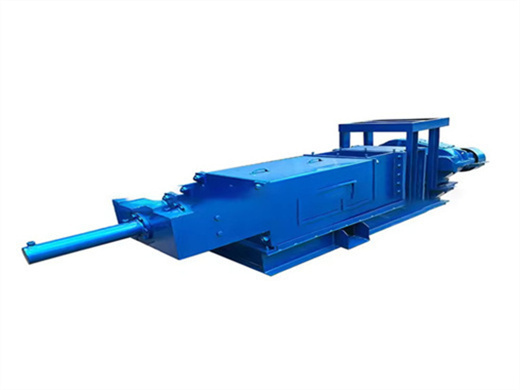

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

Customers sometimes express the desire to produce multiple types of cooking oil using a single machine. In response, it should be noted that high oil-content raw materials typically undergo pretreatment, pre-pressing, and solvent extraction methods, whereas low oil-content raw materials are directly used in the refining method after the pretreatment.

Explore the peanut press machine's role in oil yield | Duyvis

- Type: cooking oil extraction machine

- Production capacity: 1200-2500L/H

- Dimension (L*W*H): 1500*1150*1500

- Voltage: 220/380 or customized

- Weight: 1280 KG

- Main components: Engine

This machinery enables a rapid shift from small-scale production to large-scale peanut oil production lines. What’s more, the use of 304 Stainless Steel in constructing these machines ensures durability and hygiene. The machine operates for 4-8 hours, producing a cake of peanut oil, a byproduct that has its uses in defatted peanut flour

The Chinese peanut oil mystery • A maximum oil yield is 42%, in other words, 1 ton of oil requires at least 2.38 tons of peanut kernels • Chinese importers pay 850 US$ / Ton CIF for oil grade peanuts. This means their production cost are 2.38x$850= $2023 for peanuts alone. • Yet 1 ton crude oil sells for around $1250 since 2014…

Groundnut Oil Making Process (Peanut), Business Plan

- Raw Material: peanut

- Production capacity: 1-100T/DAY

- Dimension (L*W*H): 20*6*6

- Voltage: 380-450V

- Weight: 1550

- Local service location: Bangladesh, South Africa, Nigeria, Uzbekistan

Peanut oil pressing methods. Divided by pressing temperature, there are two types of peanut oil pressing methods they are hot pressing technology and cold pressing technology. Hot pressing method is the traditional process of peanut oil. Peanut oil is steamed fried and pressed, generally at a temperature above 120 ℃ with a high rate of oil

But Crushing and rolling the seeds is mostly adopted in medium and large scale groundnut oil mill plant, as the oil yield can be increased obviously. Seeds Roasting Process; The groundnut kernels are then put into the roasting machine with automatic temperature control system. It is the key step to determine the yield of peanut oil.