200kg/h cottonseed oil refinery machine in Cote d'Ivoire

- Type: cottonseed oil refining equipment

- Usage/Application: cottonseed

- Production capacity: 10tpd-100%

- Voltage: 220v

- Main components: Motor

- Weight: 240 kg

- Dimension (L*W*H): 1160*820*1260mm

- Country: botswana

120-200kg/h oil refinery plant advance in cote d'ivoire. The new refinery to be built in botswana, the Cote d'Ivoire Peace Refinery, appears to be in jeopardy even before ground is broken. Announced with much fanfare in 2007, 120-200kg/h oil refinery plant advance in cote d'ivoire. Top Oil and Gas Companies in Côte d'Ivoire.

Cottonseed oil refining method, how to refine cottonseed oil

- Type: cottonseed oil refinery machine

- Voltage: 380 V/440 V

- Power (W): 30 KW

- Certification: CE/ISO9001/BV

- Weight: 500 TON

- Dimension (L*W*H)): 1200*2800*1200 mm

The absorption rate of cottonseed oil by the human body is 98%. 3. Cottonseed oil refining process. Cottonseed oil crude oil→degumming→deacidification→washing→decolorization→deodorization→winterization→finished first-grade cottonseed oil. 4. Main equipment for cottonseed oil refining. Neutralization pot: used for acid refining

Fractionation and Refining Crude Cottonseed Oil. 30ton/day Cottonseed Oil Refinery Plant. Refining crude cottonseed oil to produce edible / cooking oil. It involves bleaching, De-acidification, deodorization, and degumming. Fractionation can get solid and liquid oil through solid and liquid separation and cooling crystallization.

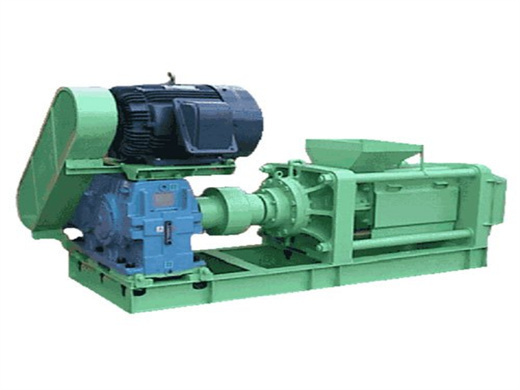

Hongde Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Usage: cottonseed oil

- Production capacity: 300-400 kg/h

- Voltage: 220 V

- Main components: motor, others

- Weight: 1500 KG

- Dimension (length x width x height): 2300x1300x2200 mm

Cotton Seed Oil Refinery Plant. Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining

Cottonseed oil contains a large amount of essential fatty acids, among which linoleic acid has the highest content, which can reach 44.0-55.0%. In addition, cottonseed oil also contains 21.6%-24.8% palmitic acid, 1.9-2.4% stearic acid, 18%-30.7% oleic acid, and 0-0.1% arachidic acid. Cottonseed oil can be used for cooking and consumption.

Cotton Seeds Oil Refinery Plants

- Type: cooking oil refining machine

- Production capacity: 100% pressed cooking oil machine

- Power (W): depends on the capacity

- Voltage: 220V/380V/440V

- Dimension (L*W) *H): 5432*2636*2345

- Weight: 850 KG

Due to clear cottonseed oil contains a large quantity of linoleic acid, it can prevent the content of cholesterol rising, maintain human body health. Human body consumption of cottonseed oil is up to 98%. Cottonseed Oil Needs Refining. It is said that refining process can reduce toxicity. Cottonseed oil is one of main cooking oil.

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.

Cottonseed Oil Extraction Plant

- Raw Material: cottonseed oil

- Production capacity: 100-500 tons

- Power (W ): As production of Russian oil refinery for sale every day

- Voltage: 380 V 440 V

- Dimension (L*W*H):Depends on the capacity of Russian oil refinery for sale

- Weight: According to the production of Russian oil refinery for sale

Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1.

The deodorization process can not only remove the odors from crude cottonseed oil, but also improve smoke point, flavor, steadily and quality of final oil. At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature.