Cottonseed Oil Production Line

- Type: cottonseed oil line

- Usage/Application: cottonseed

- Production capacity: 1tpd-1000tpd

- Voltage: 220V/380V

- Key selling points: Energy saving

- Weight: 820kg

- Dimension (L*W*H): 2050*980*1700mm

- Country: nigeria

The deodorization process can not only remove the odors from crude cottonseed oil, but also improve smoke point, flavor, steadily and quality of final oil. At last, cottonseed oil refining has a special process -- cottonseed oil fractionation process. It is to seperate the solids and liquids in cottonseed at a specific temperature.

Oil and Oilseed Processing III - Oklahoma State University

- Type: cottonseed oil refinery machine

- Voltage: 220V/380V/440V

- Power (W): 18.5KW/T

- Material: stainless steel

- Weight: 30 tons

- Dimension (L*W*H): 48m*12M*15M (30TPD)

Gossypol in crude cottonseed oil is typically removed in the miscella (mixture of oil + hexane) before hexane removal from the oil at the hexane extraction plants. In this process, the crude oil-hexane mixture (45-65 percent oil:35-55 percent hexane) is filtered to remove any meal, scale or insoluble impurities that may be carried from the

Then, the crude cottonseed oil is made and the cottonseed oil cake is discharged for next processing for feed or other usages. Oil Refining: Since the crude cottonseed oil contains high content of gossypol, it needed to be refined to improve the quality and ensure the final refined cottonseed oil is completely safe for eating.

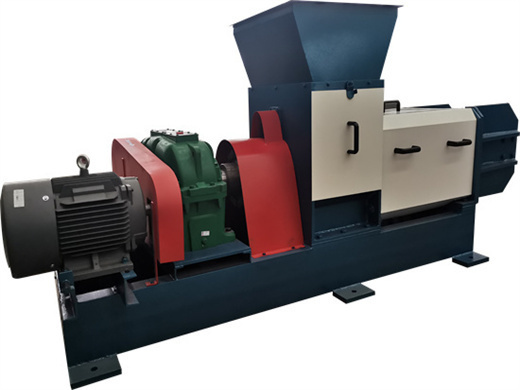

Complete Cottonseed Oil Production Lines. Cottonseed Oil

- Usage: cottonseed oil

- Production capacity: 10 TONS /DAY

- Voltage: 30 HP

- Key Selling Points: Energy Saving

- Weight: 4000 KG

- Dimension (L*W*H): 2641MM*1016MM*2489MM

For large cottonseed oil production lines with capacities of over 30 TPD, the solvent extraction method is usually adopted working together with cottonseed oil pre-press to maximize the oil yield. The large cottonseed oil production line includes a cottonseed pretreatment and pre-pressing workshop, a cottonseed cake solvent extraction workshop

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Refined Cotton Cellulose Production Line

- Type: cooking oil refining machine

- Production capacity: 3-6 kg/hour

- Dimension (length x width x height): 390*150*292 mm

- Voltage: 220 V

- Weight: 9.5kg

- Key Selling Points: High Safety Level

The use of miscella oil refining process for cottonseed oil can help remove gossypol in the process, reduce refining losses, improve oil color, improve product quality, simplify oil processing, and have better results than other refining processes. This is more suitable for refining specific oils of cottonseed oil.

Or some of the large scale oil processing plant will choose the solvent extraction method for cottonseed oil manufacturing. Refining: Since the crude cottonseed oil contains residue, solid powder and other substances, such as, gossypol. Therefore, it is necessary to remove them from the crude cottonseed oil for cooking or other purposes. After

Cottonseed Oil Processing - Oilmillmachinery.net

- Raw Material: cottonseed oil

- Oil type: cooking oil

- Shipping: sea freight

- Function: Cooking oil extraction and press plant

- Certification: CE and ISO9001

- Residue in the cake: Less than 6%

After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal. Cottonseed oil is a vegetable oil extracted from the seeds of the cotton

Zhengzhou Dingsheng Machinery Manufacturing Co., Ltd. has been established for more than 20 years. We are committed to research and development in the field of oil treatment, produces various types of oilseeds pretreatment, oil extraction and oil refining complete sets of equipment, and strives to improve the quality of the equipment and after-sales service.