Cottonseed Oil Mill Plant

- Type: cottonseed oil press

- Usage/Application: cottonseed

- Production capacity: 250-300 KG/H

- Voltage: 380V

- Weight: 2200 kg

- Dimension (L*W*H): 2000x1200x2500mm

- Power (W ): 3KW

- Country: pakistan

HOT Sale Equipment Assembly for Mini Scale Vegetable Oil Producion Line >> Tips for Running A Cottonseed Oil Mill Plant. Learn about these points before you start your own cotton seed oil mill plant: Conduct thorough research on the what you require for cottonseed oil business in terms of market size, capital and trends. Know your competitors.

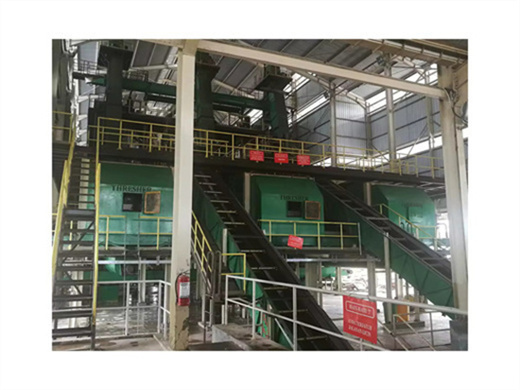

Complete Cottonseed Oil Production Lines. Cottonseed Oil

- Type: cottonseed oil processing machine

- Production capacity: 1TPD-1000TPD

- Voltage: 380V

- Weight: changed with capacity

- Dimension (L*W*H): various with capacity

- Power (W ): according to capacity

Mechanical Pressing: Suitable for small-scale cottonseed oil production or initial pre-pressing in large cottonseed oil plants. Screw oil press machines are commonly used, extracting about 70% of the oil. Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant in small cottonseed oil plants.

1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD to 20TPD; 10T/D Edible Oil Refinery Plant; 1-5T/D Edible Oil Refinery Plant; Cotton Seeds Oil Refinery Plants; Seed Oil Press. Integrated Screw Oil Press; Screw Oil Press; Peanut Oil Press

XZ32/YZ32 Oil Press

- Usage: cottonseed oil

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): According to capacity

- Oil Function: Palm kernel oil or palm oil

- Components Main: Motor

- Weight: 20000 KG

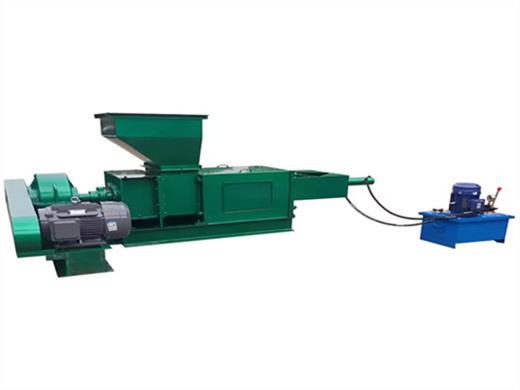

ZY / ZX28 spiral oil press is a large continuous oil press equipment, through the 09001-2000 Quality System Certification, Suitable for cottonseed,rapeseed, castor, sunflower seeds, peanuts and other high oil content of the press oil.It has the characteristics of large processing capacity, small power consumption, low operating cost, loose and not broken cake structure, easy solvent

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.

Complete Cotton Seed Oil Processing Plant

- Type: cooking oil extraction machine

- Voltage: 380 V

- Customized: Customized

- Press Materials: Sunflower, Soybean, Coconut, Peanut , Mustard

- Model: Lbzy 150

- Overall dimensions (mm): 2200*1460*1750

The cottonseed pretreatment equipment adjusts the internal structure of cottonseed to a state suitable for solvent extraction. The crude cotton seed oil and cottonseed cake can be obtained after being processed by the cottonseed oil pre-press. The cottonseed cake is transported to the leaching workshop to further produce cottonseed oil.

Large Scale Prepress Screw Oil Mill Prepress expeller is a continuous screw expeller, which is applicable for prepress-extraction process or twice press process of vegetable oil plant, can be used to press oil-bearing crops such as peanut kernel, cottonseed kernel, rapeseed and sunflower seed kernel, etc.

Factory Price Cotton Seed Oil Mill Machine for Sales | ABC

- Raw Material: cottonseed oil

- Production capacity: 10TPD

- Dimension (L*W*H): 1.2*0.78*1.1m

- Voltage: 220V380V

- Weight: 300 KG

- Main components: Motor, Pressure vessel, PLC

The cottonseed oil machine designed by Our Machinery is Screw Oil Press Machine that is now the most popular cooking oil processing machine in market since it can process various plant seeds or oilseeds such cottonseeds, sunflower seeds, peanut/groundnut, soybeans, palm kernel, sesame seeds, flaxseed, almond, moringa, coconut/copra, and more.

The pre-pressed cottonseed cake is sent to the leaching workshop, where the cottonseed oil in the pre-pressed cake is extracted by spraying and soaking with hexane solvent. The cottonseed oil leaching workshop consists of solvent leaching system, wet meal desolvation system, mixed oil evaporated stripping system and solvent recovery system.