palm oil line

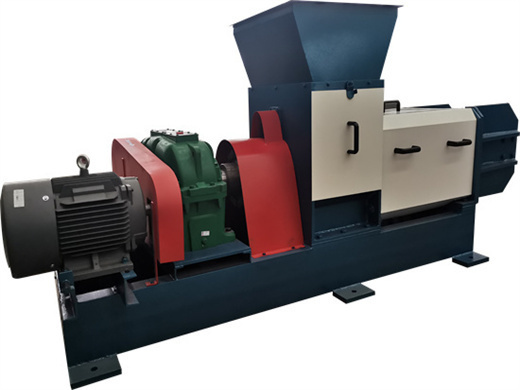

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100kg/h

- Voltage: 220V/380V/440V, 380V or customized

- Warranty: 1 year, 12 months

- Weight: 1200kg

- Dimension (L*W*H): 2600x2100x1730mm

- Country: nairobi

There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

Palm Kernel Oil Press,Oil Expeller,Oil Plant for Sale Made in

- Type: palm oil processing machine

- Voltage: 380V

- Appearance: Horizontal

- Machine: Palm Oil Grinding Machine

- Customized: Customized

- Press materials: Palm fruit oil press

Soybean oil came in second with 37 million tonnes (23%). About 38% of the oils and fats produced in the world were shipped across oceans. Of the 60.3 million tonnes of oils and fats exported around the world, palm oil and palm kernel oil make up close to 60%; Malaysia, with 45% of the market share, dominates the palm oil trade.

Our Automatic double-shaft palm kernel oil press machine is designed to meet the needs of modern palm kernel oil production, with capacities ranging from 10 TPD to 100 TPD. It features a large processing capacity, high oil yield, and long service life.

Huatai palm oil machine / FFB oil mill - Palm Oil Production Line

- Usage: palm oil

- Voltage: 110v/220v/380v/440v

- Dimension (L*W*H): 1010*780*960mm Max

- Oil residual: 1-5%

- Oil yield: 98%

- Color: Silver, red, yellow, green, blue

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

If you are going to buy palm kernel processing machine for Palm Oil Processing Plant to start palm kernel oil production business. Where you can get the best processing machines in Malaysia? QIE Machinery, the leading machinery manuafactuer in palm oil processing sector, is the BEST choice due to its high quality machinery, competitive cost and overall service. Besides, QIE Machinery strive continuously to improve the technology of palm kernel oil extraction for maximized oil output, which promising the most advanced Palm Kernel Oil Processing Machine to customers.

Palm Oil Pressing Machine

- Type: cooking oil extraction machine

- Production capacity: 100% grain roasting machine

- Power (W): 10-50 kw

- Voltage: 220 V/380 V/440 V

- Dimension (L*W*H): It depends on its capacity, according to the capacity

- Weight: It depends on its capacity

With more than 200 patented technologies as the core, Huatai Oil Machinery has overcome the high oil loss and high energy consumption problems in palm oil processing – from fresh fruit (FFB) sterilization and pressing to crude palm oil (CPO) refining and fractionation, the oil output rate of our palm oil equipment leads the industry by 5%-10%

RG-312 Oil Press Machine/Palm Kernel Coconut Solvent Extraction Machines: Ideal for large-scale Made with high-quality materials, palm kernel oil

Palm oil press production machine - Palm oil extraction machine

- Raw Material: palm

- Production capacity: 100-6000 kg/h

- Dimension (L*W*H): 390*150*292mm

- Voltage: 220v/110v

- Weight: 9.5 KG

- Main components: Motor, PLC, Others, Gears

These palm oil press production machine is the best choice for most people start palm oil processing business. 2. 15-30-45-60-80-120TPH palm oil press production machine. 15-120tph palm oil press production machine is suitable for large scale palm oil mill. The final quality of palm oil is high ,and the investment cost is also high. Work flow

Main Station of Palm Oil Extraction Plant( Whether it is a small scale palm oil machine or large scale palm oil processing plant all include the following station): 1) Palm fruit reception station; 2) Palm fruit sterilizing station; 3) Palm fruit threshing station; 4) Palm fruit digesting & pressing station; 5) Crude palm oil clarification station;