PHYSICAL REFINING OF SUNFLOWER OIL

- Type: sunflower oil plant

- Usage/Application: sunflower

- Production capacity: 10-5000T/D

- Voltage: 220V/380V/415V

- Weight: 420 KG

- Dimension (L*W*H): 1910*550*765 mm

- Power: 2.2KW

- Country: johannesburg

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

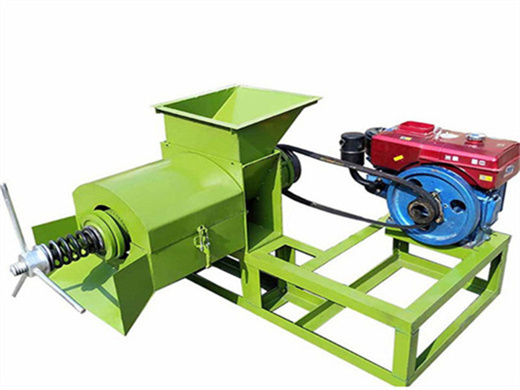

Effects of refining process on sunflower oil minor components

- Type: sunflower oil refinery machine

- Production capacity: 40~800kg/h

- Voltage: 350v

- Main components: motor, gear, motor, gearbox

- Weight: 300 KG

- Dimension (L*W*H): 800*650* 1100

Oil (HOSO), Mid Oleic Sunflower Oil (MOSO), High Steraric High Oleic Sunflower Oil (HSHOSO) and High Palmitic High Oleic Sunflower Oil (HPHOSO). These four other composi-tions are interesting for different usages like: biodiesel (Del Gatto et al., 2015), lubricant (Al Mahmud et al., 2013)orits ability to replace hydrogenated fats (Salas et

Crude rapeseed oil contained 656 mg/kg of total tocopherols, followed by high oleic sunflower with 373 mg/kg of tocopherols and classic sunflower oil with 332 mg/kg of tocopherols. The most serious refining processes were bleaching and physical deodorization process, the tocopherol losses being 14.9-17.4% and 20.2-27.1%, respectively.

What Are Sunflower Oil Refining Process Techniques?

- Usage: sunflower oil

- Production capacity: 5TPD-100TPD

- Voltage: 380V/50HZ

- Main components: Motor

- Weight: 140kg

- Dimension (L*W*H): 880*440 *770mm

The rational design of the refining process is crucial for the development and competitiveness of investing sunflower oil refining process plant. It can eliminate bottlenecks and waste in the production process, enhance refining quality and production efficiency, reduce costs, thereby increasing output and profits.

Semi-continuous refining process has a daily capacity of 30~50 tons of seed oil. It can be used for different types of oil refining, and it has advantages of low power consumption, better refining rate than batch-type and traditional semi-continuous processes. Full continuous refining process has a production capacity of more than 50 tons per day.

Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: cooking oil refining machine

- Production capacity: 15 TONS /DAY

- Dimension (L*W*H): 2261MM*686MM*1423MM

- Voltage: 30 HP

- Weight: 5500 KG

- Main components warranty: More than 5 years

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

We design and develop complete integrated refinery plant and system specially for sunflower oil. Sunflower oil is considered to be one of the most stable oils for frying. The demand for oils with a lower degree of unsaturation than those of traditional oils has significantly increased the availability of oils of high thermostability.

Extracting and refining steps of sunflower oil. | Download

- Raw Material: sunflower

- Production capacity: 400 kg/h

- Dimension (L*W*H): 320*150*350 mm<br /Weight: 6.6 KG

- Voltage: 220 V

- Main components: no

- Oil type: cooking oil

Download scientific diagram | Extracting and refining steps of sunflower oil. from publication: Effects of refining process on sunflower oil minor components: A review | Sunflower oil is well

DVC Process Technologists is one of the leading manufacturer and supplier of Edible Oil Refinery and provides complete service including design, installation, commissioning and automation of vegetable oil refining plant for different crude vegetable oils. We have over 220+ Edible Oil Refinery installations worldwide.