Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil machine

- Usage/Application: cottonseed

- Production capacity: 1-80T/D

- Voltage: 220v-380-415v

- Weight: different according to capacity

- Dimension (L*W*H): 430*230*350

- Power ( W): according to capacity

- Country: botswana

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

Cottonseed oil mill plant manufacturers| Cotton Seed Oil

- Type: cottonseed oil processing machine

- Product Residual oil in cake: 1%

- Keyword: sunflower seed fryer sunflower

- Extractor dimension (L*W*H): according to capacity

- Voltage: 380V or 440 V

- Used for: sunflower seed fryer

Cottonseed Oil Extraction Process. Our cottonseed oil extraction plant uses a well-structured process to extract premium oil from cotton seeds. With precise cleaning, dehulling, and solvent extraction, we ensure maximum yield and purity for various industrial and edible applications.

One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple in nature and can be used to extract oil from various seed plants. The screw cottonseed oil press is a mini cottonseed oil machine that can be used for small-scale extraction oil plants.

Cottonseed Oil Mill Plant

- Usage: cottonseed oil

- Production capacity: 1000-1500g

- Voltage: 220V/110V

- Main components: Others

- Weight: 11 KG

- Dimension (L*W*H): 460*160*280mm

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cotton seed oil making is one of the HOT applications of cotton by-product. In 2019, the global cottonseed oil output was 4476 million tons, up by 3.8% compared with the same period last year, and the global volume of expeller-pressed cottonseed oil was 338,800 tons, an increase of 2.7% over the same period last year. Besides, the global import

Mini/Small Solvent Extraction Equipment for Cottonseed Oil

- Type: cooking oil extraction machine

- Capacity: 200kg/H

- Weight: 650kg

- Power: 7.5kw

- Size: 1700*600*1130

- Pressing: Suitable for Sunflower

Cottonseed, the seed of cotton plant, is a main oil crop in the world. The oil content is up to 35~45% and the protein content is about 39%. Cottonseed oil contains a lot of essential fatty acids for human consumption. The refined cottonseed oil is popular edible oil around the world. (Read more: Edible Oil Manufacturing Plant Cost >>)

Scientific processing of Cotton Seed Processing results in extraction of nearly entire cottonseed oil, while the oil cake obtained by traditional method still contains about 7% residual oil. This high residual oil is not required by the animals but ironically much in demand because of misconception among the dairymen.

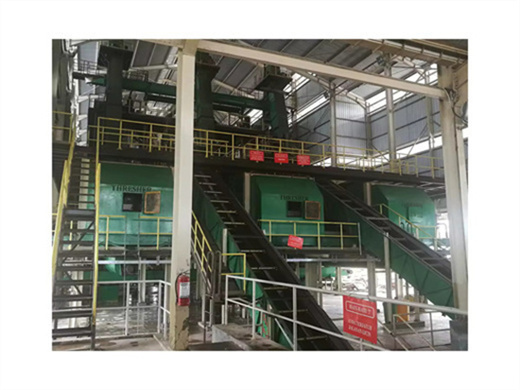

Cottonseed Oil Processing Plant | Extraction Flow

- Raw Material: cottonseed oil

- Production capacity: 1-500T/D

- Power (W) : depends on the cooking oil machine mode

- Voltage: 380V-415V

- Dimension (L*W*H): depends on the cooking oil machine mode

- Weight: depends on the cooking oil machine mode cooking oil machine

Cottonseed Oil Decolorization. The main purpose of bleaching is to remove pigments from cottonseed oil to improve the color and appearance of the oil. First, we need to heat the degummed (or deacidified) cottonseed oil to 110-120°C. Second, add 0.5-1.5% of an adsorbent such as activated carbon or clay.

We supply a great number of seed oil making machines including cotton seed oil expeller and automatic oil press for other plant seeds. We also offer turnkey solutions for complete set of oil mill plant, capacity ranging from 1 TPD to 6000TPD. Feel free to tell us your oil manufacturing needs and we will help you make the best plan!