Cottonseed Oil Mill Plant

- Type: cottonseed oil processing machine

- Usage/Application: cottonseed

- Production capacity: 100% baking production

- Voltage: 220 V/380 V/440 V

- Weight: Depends on its capacity

- Dimension (L*W*H)): Depends on its capacity

- Power (W): Depends on its capacity

- Country: uganda

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cottonseed oil mill plant manufacturers| Cotton Seed Oil

- Type: cottonseed oil processing machine

- Production capacity: cooking oil production

- Voltage: 220V/380V/440V

- Weight: 850 KG

- Dimension (L*W* H): 5432*2636*2345

- Power (W): depends on capacity

Experience improved performance with our advanced cottonSeed oil solutions. Boost your cotton oil production with our premium cotton seed oil extraction machines. As leading Cotton Seed Oil Extraction Machine manufacturers, we prioritize precision, efficiency, and high quality in our processing equipment.

One of the widely used machine used in cottonseed oil manufacturing plant is screw cottonseed oil machine, a type of cottonseed oil machinery. It’s very simple in nature and can be used to extract oil from various seed plants. The screw cottonseed oil press is a mini cottonseed oil machine that can be used for small-scale extraction oil plants.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Usage: cottonseed oil

- Production capacity: 7.5w

- Voltage: 220V/380V/440V, 220V/380V/440V

- Material: 304 stainless steel

- Weight: 1100KG, 1200kg

- Dimension (L *W*H): 1700* 1300*1750mm, 1700*1300*1750mm

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

The equipment cost of 5ton per day small cotton seed oil manufacturing workshop is about $8000. The larger the output, the greater the difference of investment cost between different project design. Start Small Cottonseed Oil Milling Business. Here is the main equipment for small scale cotton seed oil mill plant:

Cottonseed Oil Processing Machines Set up Complete Oil Mill Plant

- Type: cooking oil extraction machine

- Production capacity: 250-300 KG/H

- Power (W ): 3KW

- Voltage: 380V

- Dimension (L*W*H): 2000x1200x2500mm

- Weight: 2200 kg

After refining, cottonseed oil meeting national standards can be obtained and sold on the market to obtain profit income. So far, the technological process of cottonseed oil production by solvent has also ended. (Related Project: Cottonseed Oil Refinery Plant in Afghanistan >>) Cottonseed Oil Refining Machine. Cottonseed Oil Fractionation

Cottonseed oil refining machine is divided into intermittent, semi-continuous and fully continuous three kinds, including degumming, deacidification, decolorization, deodorization 4 steps When we finish these 4 steps, we can get the cotton seed oil. Cottonseed oil refining machine. The above is the introduction of the complete cotton seed oil

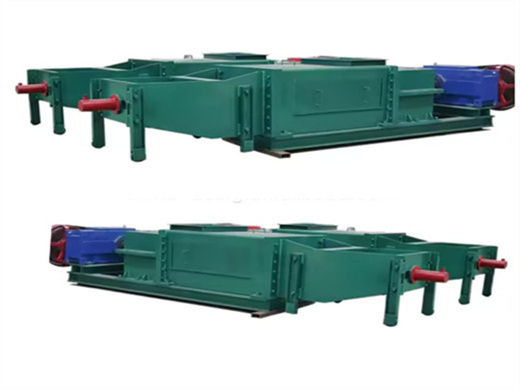

Small Scale Oil Mill of Cotton Seed

- Raw Material: cottonseed oil

- Production capacity: 500-800 Kg/H

- Dimension (L*W*H) : 8500x2250x2600 mm

- Voltage: 220 V/380 V, Customized

- Weight: 1700 KG

- Main components: PLC, Motor

Cottonseed Oil offers a unique business opportunity. By 2028, the global cottonseed market will reach a value of over 5 billion dollars. It is foretasted to grow by 3.2% over the next few years. This increased demand for cottonseed oil is mainly due to the food processing and snack food industry.

Cotton Seed Oil Processing Machine (1~20T/D) Different from traditional screw oil press, our cotton seed oil machine is available with heating device. Therefore, you have the choice to save preheating time of the machine itself. More importantly, it can greatly improve the oil output as well as quality of crude cotton seed oil.