Huatai palm oil machine / FFB oil mill - Palm Oil Production Line

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: according to capacity

- Voltage: 220v,380v,440v

- Weight: 1050 KG

- Dimension(L*W*H): 1610x615x1260mm

- Power(W): according to capacity

- Country: zambia

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Palm Oil Pressing Machine (Oil Extraction)

- Type: palm oil processing machine

- Production capacity: 5T~10T/D

- Voltage: 220V/380V

- Weight: according to capacity

- Dimension (L *W*H): 5432*2636*2345

- Power (W): according to capacity

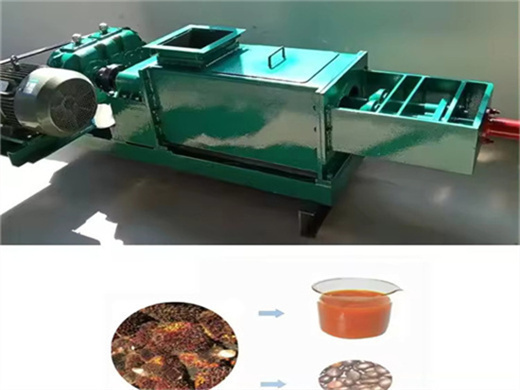

In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts. Hydraulic presses and the older centrifuges have been deemed almost redundant today as palm oil processing plants these days use specifically designed screw-presses much like the

A leading, trusted partner for crude palm oil processing mills. A full range of palm oil milling equipment and machinery, including separation technologies from the industry’s leading developer. Innovations for recovering a higher percentage

Palm Fruit Threshing Processing Machinery Equipment

- Usage: palm oil

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

Specialized in designing and constructing large scale palm oil milling plant including all machines to manufacture palm oil to international standards. The capacity ranges from 3 tonnes to 60 tonnes of FFBs per hour. Our palm oil mill projects are designed with mechanical handling systems including pipelines, pumps, screw conveyors and bucket.

It has the advantage of low core crushing ratem high extraction performancem no special moisture contents requirements on raw material, excellent manufacturing process, compact structure, large output, stable operation, easy maintenance and long durability. At present, palm oil press has been widely used by many palm oil producing countries.

Palm Oil Mill Plant Production Line - HUATAI OIL MACHINE

- Type: cooking oil extraction machine

- extractor type: rotocel extractor

- Overall cooking oil extraction rate: 12%- - 18%

- Solvent consumption: ≤ 3Kg/T (6 #solvent oil)

- After refinery, oil in cake: 1%

- Overall extraction protein: 50%

Huatai Palm Oil Mill Plant Machine. Huatai Palm Oil Mill Plant Machine Offers Complete Palm Oil Mill Plant Solutions. In addition, we also provide a professional technical team to design the whole palm oil mill plant and help customers maximize commercial profits by making the most use of the by-products produced during the process of palm oil

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0℃ to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Palm Oil Machine - Palm Oil Production Line

- Raw Material: palm

- Voltage: 380v 440v

- Dimension (L*W*H): As sesame seeds oil mill capacity

- Power (W): Depends on the capacity of sesame seed oil mill

- Weight: As sesame seeds oil mill capacity

- Certification:ISO9000 CE BV

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.