new design edible oil sunflower oil refining machine in malawi

- Type: sunflower oil making equipment

- Usage/Application: sunflower

- Voltage: 220 V/380 V

- Dimension (length*width*height): depends on capacity

- Advantage: very efficient and economical

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, Motor, gearbox

- Weight: depends on capacity

- Country: malawi

Brief introduction of sunflower oil refinery machine Purpose: Oil refining is based on the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil, getting standard oil.

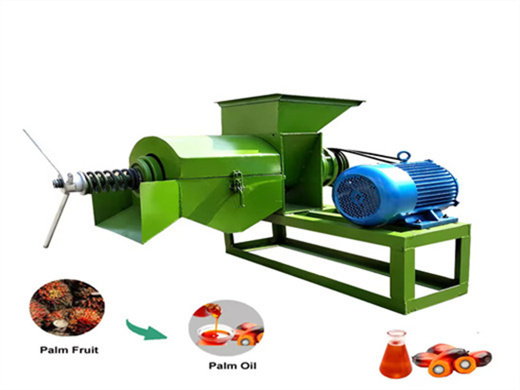

Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil refinery machine

- Production capacity: 10-500 tons/day

- Voltage: 220 V

- Main components: Motor

- Weight: 11 KG

- Dimension (L*W*H): 540*250*360 mm

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

Sunflower Oil Refining Equipment List; Sunflower oil hydration and degumming equipment: 1. Hydration tank (intermittent, same as alkali refining pot) 2. Vacuum dryer 3. Desolventizer (dedicated to remove residual solvents from leaching branched hairy sunflower oil) Sunflower alkaline refining and deacidification machines: 1. Alkali refining pot 2.

PHYSICAL REFINING OF SUNFLOWER OIL

- Usage: sunflower oil

- Warranty: 24 months

- Customized: Customized

- Automatic: Half or full

- Control: CNC or PLC

- Advantage: Wide use

crude oil quality. Physical refining of sunflower oil is discussed in details. Recent developments in the field of processes, equipment and control have made possible to refine by physical way the high phosphatide containing seed oils as well. Special degumming processes, improved performance of bleaching materials, better design of

The demand for oils with a lower degree of unsaturation than those of traditional oils has significantly increased the availability of oils of high thermostability. Refining the crude sunflower oil on our Tinytech refinery machine will eventually produce an additive free product having good oxidative, flavor and cold-test stabilities. Idea

Sunflower Oil Making Machines for Sale

- Type: cooking oil refining machine

- Production capacity: 5TPD

- Dimension (L*W*H): 670*950*1460(mm)

- Voltage: 380V/220V

- Weight: 950kg

- Main components: engine, hydraulic system

You are welcome to inquire about the project details and costs of our sunflower oil extraction machine and refinery machine! 10 ton/d sunflower oil processing plant in Moldova; 150 ton/d sunflower oil manufacturing plant in Russia; Sunflower Oil Making Process. Sunflower oil manufacturing is a complex process involving various stages.

- Produces cleaner, ready-to-use oil or oil ready for further refining. 5. Oil Refining Machine (Optional): - Used for refining crude sunflower oil to remove unwanted components such as free fatty acids, phospholipids, and pigments. - Results in clearer, higher-quality oil that has a longer shelf life and better taste.

sunflower oil processing machine suppliers manufacturer in

- Raw Material: sunflower

- Production capacity: according to capacity

- Power (W): according to capacity

- Voltage: 220v,380v,440v

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

Usage: Peanut, Sunflower, Soybean, Castor, Rapeseed, Sesame, cooking, Copra, Grape Seeds, Shea Nut, Safflower, Germ, Seeds, , Oil; Type: sunflower oil mill line

It is suitable for refining various crude vegetable oil, such as tea seed oil, groundnut oil, palm oil,soybean oil, cotton seed oil, rapeseed oil, camellia seed oil, corn germ oil, rice bran oil, sunflower seed oil, etc. Main Equipment: degumming tank, nentralizing tank, centrifuge, heat exchanger, decolorization tower, dedorization tower, etc.