palm oil line

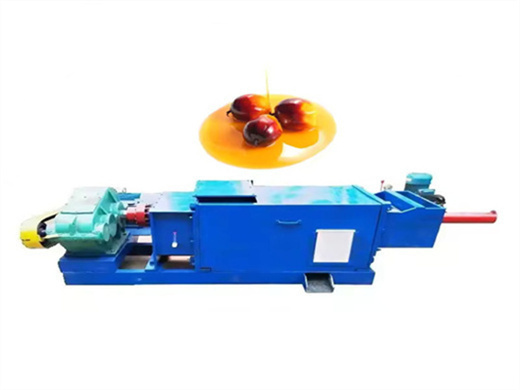

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Raw Material: Flowers

- Supply Type: OEM/ODM

- Product Purity: 100% Natural Aromatherapy Oil Blend

- Feature: Moisturizing, Anti-wrinkle, Anti-aging, Nourishing, Skin and hair care

- Ingredient: Clove

- Country: lusaka

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

Huatai palm oil machine / FFB oil mill - Palm Oil Production Line

- Type: palm oil processing machine

- Production capacity: 100 kg/h

- Voltage: 220 V/380 V

- Main components: motor, pump, PLC, oil making machine

- Weight: 230 kg

- Dimension (length x width x height): 1200x800x1160 mm

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Huatai palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

The lusaka customer is a middleman. And he is a businessman engaged in various industries. He bought the palm kernel oil extraction machines because he wanted to engage in the palm kernel oil press business. Because the lusaka customer is most concerned about the after-sales issues of the palm kernel oil extraction machines.

ANNEX 1: Major manufacturers and designers of palm processing

- Usage: palm oil

- Customized: Customized

- Machine: Cooking oil processing machine

- Dry or wet type: Cooking oil processing machine wet type kitchen Malaysia

- Raw material: vegetable seed

- Capacity: 1t/H 2t/H 5t/H Cooking oil plant

The nutcracker, kernel/shell separator and palm kernel expeller are produced to handle palm kernel. The expeller has machined flights on a single shaft with threaded backpressure cone. Generally machines are produced having a 1 tonne/hr capacity for palm oil while the palm kernel machines have rated throughputs of 150-250 kg/hr.

2) Crude oil centrifugal filter: Quickly separate the pressed oil and pomace to obtain cleaner crude oil. 3) Palm kernel special oil pressing machine: Specially designed for palm kernels of different sizes, easy to clean and low maintenance cost. 3. Palm Oil Refining and fractionation equipment

Palm Kernel Oil Press / Extraction Machine Manufacturers

- Type: cooking oil extraction machine

- Production capacity: 100%

- Power (W): 256KW

- Voltage: 400/380/220V

- Dimension (L*W*H): 23*22 *15M

- Weight: 76290KG

Palm Kernel Oil Press Machine We are one of the leading manufacturer of Palm Kernel Oil Press Machines which is manufactured in our state-an-art manufacturing unit. These Palm Kernel oil extraction machine are made in India product with European and US standard.

The hydrocyclone separates palm kernel from shell particles by using of their proportion. After palm oil pressing process, solids parts (mixtures of palm fibre and nuts) will be discharged out of the screw press. In palm kernel recovery plant, the nuts and fibre will be separated by physical method.

Palm Oil Pressing Machine

- Raw Material: palm

- Production capacity: 1-500T/D

- Power (W): 5.5-22KW

- Voltage: 220V/380V/440V

- Dimension (L *W*H): 48m*12M*15M(30TPD)

- Weight: 30 tons

With more than 200 patented technologies as the core, Huatai Oil Machinery has overcome the high oil loss and high energy consumption problems in palm oil processing – from fresh fruit (FFB) sterilization and pressing to crude palm oil (CPO) refining and fractionation, the oil output rate of our palm oil equipment leads the industry by 5%-10%

In pressing stage, mechanical screw palm oil pressing machine is used to extract the oil out of digested palm pulp which is a mixture of oil, water, fibre and nuts. Hydraulic presses and the older centrifuges have been deemed almost redundant today as palm oil processing plants these days use specifically designed screw-presses much like the