A Plant Design for Mechanical Extraction of Nmanu Aki (Palm

- Type: palm oil extraction equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 150-300 kg/h

- Voltage: 380 V

- Main components: Motor

- Weight: 1200 kg<br /Warranty: 1 year, 18 months

- Dimension (L*W*H): 2000x1400x1850 mm

- Country: johannesburg

palm oil, which is obtained from the flesh of the fruit. The design objective in this case is to redesign and fabricate a palm kernel oil extraction plant (mechanical) that will produce 200kg of palm kernel oil per day using palm kernel. In the extraction of palm kernel oil, many processes are involved namely: Traditional, solvent extraction and

4. TRADITIONAL TECHNIQUES AND INNOVATIONS IN SMALL-SCALE PALM

- Type: palm oil processing machine

- Production capacity: 1-2000TPD

- Voltage: 220V

- Weight: 1300kg

- Dimension (L*W*H): 46*32 *36cm

- Power (W): 5.5 kW

4.1 Mechanical extraction. Pounding (digestion) and oil extraction are the most tedious and essential operations in traditional palm fruit processing; therefore early efforts concentrated on these tasks. In small-scale processing, digestion, the breaking up of the oil-bearing cells of the palm fruit’s mesocarp, is the most labour intensive.

Mechanical Oil Extraction (Cold or Hot Pressing) Mechanical extraction of palm kernel oil is a more efficient and scalable method compared to traditional manual techniques. It involves the use of hydraulic or screw press machines, which apply pressure to extract oil from the palm kernels.

Traditional VS Mechanized Palm Kernel Oil Extraction Methods

- Usage: palm oil

- Production capacity: 50-500 kg/h

- Voltage: 220 V/110 v

- Main components: Motor, pump, PLC

- Weight: 7.8 KG

- Dimension (L*W*H): 430*290* 220

Advantages of using mechanized palm kernel oil extraction method: Palm kernel oil extraction methods. 1. The use of machine production greatly reduces labor costs and has higher production efficiency. 2. The degree of automation of mechanized production is high, and the oil yield of palm kernel oil is higher.

The traditional oil extraction method is to fry palm kernels in old oil or simply heat the dried nuts. The fried kernels are then pounded or ground to a paste in a motorised grinder. The paste is mixed with a small quantity of water and heated to release the palm kernel oil. The released oil is periodically skimmed from the top.

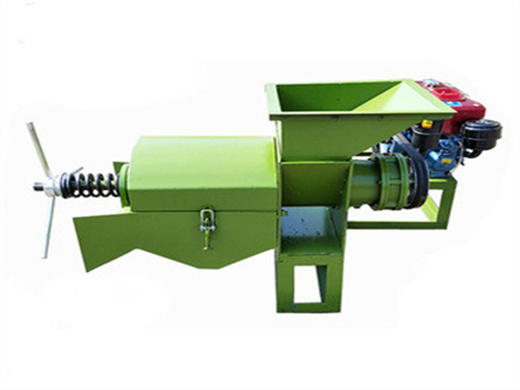

Mechanical extraction of palm kernel oil by screw press

- Type: cooking oil extraction machine

- Production capacity: 100% oil press machine

- Power (W): 5.5 ~ 18.5 KW

- Voltage: 220V/380V/440V

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Weight: 950KG

Palm kernel oil (PKO) extraction and refining techniques involves operations such as sorting of kernels, handling, mechanical pressing, filtration of crude oil, thermal, chemical and physical

Palm kernel oil is an important component of African cuisine and rural industry. The traditional method of oil extraction currently utilized in rural areas is arduous, time consuming and inefficient. To mechanize the oil extraction process, a screw press implement for the multi-function platform diesel engine was designed.

Design and Construction of a Palm Kernel Oil Extraction.pdf

- Raw Material: palm

- Production capacity: 1-100TPH

- Power (W) : 18.5 KW

- Voltage: 220V/380V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 15TONS

In this research work, the design and construction of a palm kernel oil extraction machine was carried. The results obtained with the palm kernel oil extraction machine and traditional methods are shown in Table 1. From the graph, the mechanical method via the use of palm kernel extraction machine is more efficient than the traditional method.

Tel:+86-027-8790 7188 Cell Phone: +86 135 0967 2546 Whatsapp: +86 135 0967 2546 E-mail: support@palmoilmills.org