How to Start Mini Soybean Oil Mill Plant | 1~30 Tons/Day

- Type: soybean oil mill

- Usage/Application: soybean

- Print dimension: 600*1900/2600/3200

- Plate type: Flatbed printer

- Dimensions (L*W*H): 2640*1540*1570mm

- Voltage : 380V, 380V/50HZ(three-phase 4 wires)

- Color and page: Multicolor

- Country: botswana

Estimates of the total cost range from $ 7,000 to as high as $100,000. For people who is going to start a mini or small soybean oil making business. It is absolutely the BEST choice. (Read more about Soybean Oil Business Plan >>) 1~30TPD Mini Soybean Oil Mill Plant. Mini Soybean Oil Mill Plant at Low Cost

Starting a Small Scale Soya Oil Plant

- Type: soybean oil processing machine

- Filling principle: Pressure

- Packing container Lifting structure: Pneumatic lifting

- Packaging material: Plastic

- Packaging: Bottle

- Structure: Linear

You can have cheaper land if you buy/rent it in a rural area. The main thing that will consume most of the budget will be soybean oil mill machines. Generally, the cost of establishing a mini/small scale small scale soybean oil plant ranges from $5,500 to $35,000. Soybean Oil Mill Machines for Sales. Small Soybean Oil Mill Project Report - ABC

Benefits of Building a Mini Soybean Oil Mill Plant. First, this mini soybean oil plant is user-friendly and not labor-intensive. For your information, you can ably operate the plant with a workforce of two to three people only. The operating environment of the plant is safe. Secondly, you can set up the unit hassle-free.

Mini Soya Oil Mill Plant

- Usage: soybean oil

- Production capacity: 5-500 TPD

- Voltage: 440 V

- After-sales service provided: Engineers available to service machinery abroad.

- Certification: ISO,CE

- Weight: 500 TONS

A mini soybean oil mill plant is a small-scale facility designed for the extraction of oil from soybeans. It is typically used by small or medium-sized businesses and individuals who wish to produce soybean oil with lower investment and limited space. Here's an overview of the components, processes, and advantages of a mini soybean oil mill plant:

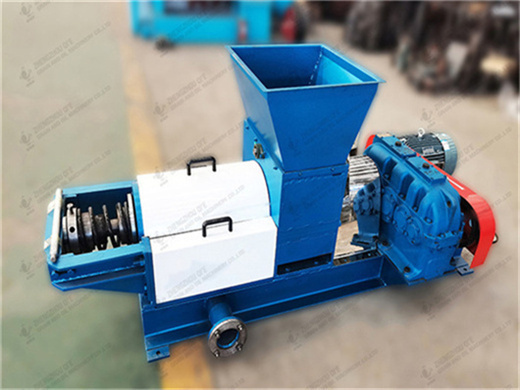

1. The pressing parts of the mini oil mills (5-20TPD)-After a lot treatment from the oil seeds, the raw material is sent to the pressing workshop, where the oil is extracted from the seeds and nuts. The mini oil mill connects a series of tools in order to extract the oil, some of the tools are- screw elevator, screw press, cleaning sieve, etc.

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Type: cooking oil extraction machine

- Production capacity: 1TPD

- Voltage: 220V/380V/440V

- Warranty: 1 year, 12 months

- Weight: 150 KG

- Dimension (L*W*H): 920 x 390 x 750mm

We are a global Manufacturer & Exporter of Soybean Oil Mill Plant. Our offered oil mill machinery & equipment is designed using high quality material and modern technology at our state of the art facility. We undertake turnkey project for the complete Soybean Oil Extraction Plant which can extract Soya Oil, Full Fat Soya Meal, Low Fat Soya Meal

This small scale oil mill production assembly unit is a good choice of manufacturing cooking oil from soybean, peanut kernel, sunflower seeds, cotton seeds, sesame seeds, maize germ and many other oil bearing materials. Below is the main machinery included in the mini oil processing unit.

Interested in Setting up a Mini Soybean Oil Production

- Raw Material: soybean

- Production capacity: 1-1000 TPD

- Power (W): 1-30kw

- Voltage: 220V/380V/415V

- Dimension (L*W*H): 1200*400*900mm3

- Certification: ISO9001

Moreover, mini soybean oil production assembly unit can process many other oil seeds, such as peanut kernels, rapeseed, cotton seeds, sunflower seeds, corn seeds, palm kernels, and sesame seeds. The automatic oil press machine is the most important equipment in the mini soybean oil production assembly unit, its components include the oil press

Soybean milling is the process of taking whole soybeans and processing them into a usable product: soybean meal. Processing soybeans typically involves de-hulling soybeans and then crushing or cracking them so they can be used for a wide range of applications. Although soybean milling is a common practice, not every milling method is optimal.