Refinery profile: Abidjan I cracking refinery, Cote d’Ivoire

- Type: peanut oil refinery plant

- Usage/Application: peanut, groundnut

- Production capacity: 80-600 KG/H

- Voltage: 110V, 280V, 380V, 440V

- Weight: 1050 KG

- Dimension (L*W*H): 430*230*350

- Power (W): according to capacity

- Country: botswana

This information is drawn from GlobalData’s Oil & Gas Intelligence Center, which provides detailed profiles of 34,000+ oil and gas fields, 400,000+ exploration blocks, 1,100+ LNG terminals, 3,400+ gas processing plants, 5,000+ storage terminals, and 8,000+ pipelines, 1,400+ refineries and 13,000+ petrochemical plants worldwide.

Cooking Oil Refining Plant. Edible Oil Refining Equipment

- Type: peanut oil refinery machine

- Production capacity: 20-2000TPD

- Voltage: 380V

- Weight: standard

- Dimension (L*W*H): standard

- Power (W): Standard

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.

Imported from Japan, it was due to arrive at the main commercial port in botswana. However, initial route surveys identified that the bridge between the port and the refinery didn’t have the capacity to bear the load. The convoy would have to take a detour and travel a longer distance through the busy streets of Abidjan.

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Usage: peanut oil

- Voltage: 380V-415V

- Power (W): depends on capacity

- Certification: ISO9001/BV/CE

- Weight: According to capacity

- Dimension (L*W*H): According to your requirements.

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

This is a mini copra oil refinery plant built in Côte d'ivoire. It is based on semi-continuous refining process. The production capacity is 10... 10TPD Soya / Peanut Oil Producing Plant in lesotho This soybean and peanut oil producing equipment set is designed for one of our customer in lesotho, daily consumption of 10 tons of raw materials a...

Small Edible Oil Refinery Plant

- Type: cooking oil refining machine

- Production capacity: 10-2000T/D cotton seed milling machine

- Power (W): according to the capacity of the cotton seed milling machine

- Voltage: match with local voltage, match with local voltage

- Dimension (L*W*H): according to the capacity of cotton seed milling machine

- Weight: according to the capacity of cotton seed milling machine

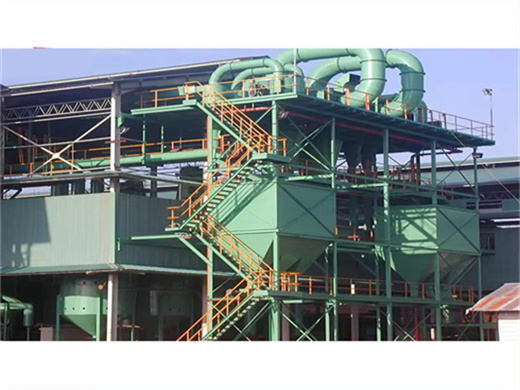

Equipment Included in The Small Edible Oil Refinery Plant. Edible Oil Refining Process . Heat Conduction Oil Furnace: 1 set (Produce enough heat for the refining sections, temperature≥240℃) Steam Generator: 1 set (Produce steam for the deodorization process) Refining Pot: 2sets (Remove the gum, phosphoric acid etc.)

SMB Abidjan Refinery is located at Abidjan, Lagunes, Cote DIvoire. Location coordinates are: Latitude= 5.25976, Longitude= -3.99239. This infrastructure is of TYPE Crude_Oil_Refineries and CATEGORY Fuels and Resources with a design capacity of 65200 bbl/day. .

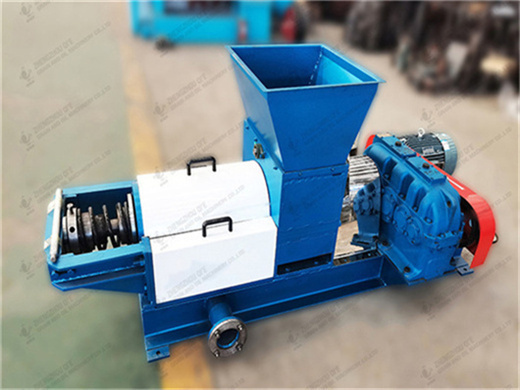

Batch type peanut oil refinery plant and continuous peanut

- Raw Material: peanut

- Production capacity: 50 - 600 kg/

- Warranty on main components: 6 months

- Weight: 0 KG

- Main components : gear

- Oil type: cooking oil

Cotinuous peanut oil refinery plant with capacity (50-600tpd) General speaking, for 30tpd and above, the full-continuous peanut oil refinery plant is much better for large scale edible oil refinery plant. Though the cost of full-continuous peanut oil refinery plant is high, the quality is much more steady and average.

2) Peanut oil solvent extraction workshop: After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery plant: