A Guide to Setting Up a Palm Kernel Oil Refinery Plant

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Automatic grade: Semi-automatic

- Production capacity: 1TPD-1000TPD

- Dimension (L*W*H): 1910*550*765 mm

- Power (W): 7.5kw

- Voltage: 220V/380V

- Country: ethiopia

Setting up a palm kernel oil refinery plant is no piece of cake. As if researching the market - from finding a reliable source for the inputs of your process to identifying demand for your final product - does not have its own set of challenges, the process of setting up a palm kernel oil refining operation also comes with a fair bit of complexity.

Setting Up an Edible Oil Refinery Plant: Key Considerations

- Type: palm oil refinery machine

- Production capacity: 100TPD

- Voltage: 220/380

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, others

- Weight: 280 KG

- Dimension (L*W*H): 1400 *860*1260

And you’ll likely be rewarded with a intelligently designed, beautifully engineered, and highly profitable edible oil refinery plant. Let’s get straight to step 1. Doing your Research Be it an edible oil refinery plant or any other production facility, the first step is always to gather as much information as you possibly can.

PALM KERNEL OIL PROCESSING PROCESS. Mechanical extraction processes are suitable for both small, medium and large capacity operations. The basic steps are : Palm Nut Cracking & Shell Separation Unit; Palm kernel Mechanical Pressing Unit; Palm Nut Cracking & Shell Separation Unit. Palm Nut is one of the byproduct of Palm Oil Extraction Plants.

Palm Oil Refinery Plant, Manufacturing Vegetable Oil Products

- Usage: palm oil

- Production capacity: 100% canola oil refining plant

- Voltage:220V/380V/ 440V

- Weight:50tons

- Dimension (L *W*H):48m*12M*15M(50tons)

- Power (W): 5.5-22KW

Palm oil deodorization is the final process of edible palm oil refinery plant. It is a result of heating-crushing and heating extraction development. Odiferous material and other minor undesired particles are removed from the crude palm oil or palm kernel oil in the deodorization process of palm oil.

Global footprints are the result of providing Tailored Solutions, Sound Advice, Economical Equipments and Robust Durability of our Refinery Plants and Machinery. Round-the-clock service approach has helped in Outstanding Customer Satisfaction.

Supply vegetable oil refinery plant for refining crude palm

- Type: cooking oil refining machine

- Raw material: Leaves

- Ingredient: Other, Eucalyptus

- Available quantity: 4600 kg

- Features: Skin Revitalizer, Blackhead Remover, Anti-Puffiness, Dark Circles, Other, Moisturizing, Anti-Wrinkle, Anti-Aging, Whitening, Firming, Nourishing

- Botanical Packaging: Aluminum bottles, Glass bottles, Plastic drums, GI drums

DOING Holdings - Henan Glory Oils & Fats Engineering Co., Ltd is a leading manufacturer specialized in cooking oil making machine with capacity 10-2000TPD.We can offer cooking oil press machine,oil extraction machine,oil refinery & fractionation plant.

We possess technological expertise in the manufacturing of Edible Oil Refinery Plants and Vegetable Oil Refinery Plants. Our machinery is suitable for crushing and refining of all types of oil seeds such as groundnut, sunflower, soyabean, palm kernel, mustard, copra, sesame seed, rapeseed, linseed, cotton seed etc.

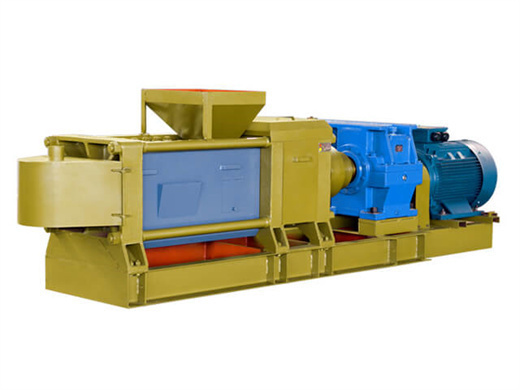

Small Scale Palm Kernel Oil Extraction Machine for Automatic

- Raw Material: palm

- Production capacity: 150-300 kg/h

- Dimension (L*W*H): 1900* 1400*1700mm

- Voltage: 220v/380v/Customer request

- Weight: 1100 KG

- Main components: Motor

Palm oil processing is a profitable business in africa. If you are planning to start a palm oil business, you must first invest in palm oil processing machines. This means you need to know the price of the palm oil processing machines for better financial planning of your business. In this article, we will discuss about palm oil milling machines and their prices in the african market.

Whereas hard oils like Palm Oil, Palm kernel oil, Shea butter and also lauric oils like coconut oils plus rice bran oil are with high FFA content. Although Chemical refining will generate acceptable quality of refined oil, the soap formed with caustic soda will also entrap some oil and excess caustic used during the process will convert neutral